Single pilot operated valve Dozer valve

Product Specifications

| Product Model | Multiple pilot operated valve |

| Inlet pressure | Max 50 bar |

| T Port Back Pressure | 3 bar |

| 0il | Mineral oil |

| Viscosity Range | 10~380mm'/s |

| 0il Temperature | -20°C~80°C |

| Cleanliness | NAS Level 8 |

| Oil port type | IOS 1179 G1/4 |

Product Features

Single pilot operated valve has the following characteristics:

Independent Control: A single control valve can independently control parameters such as fluid flow, pressure and direction to achieve precise control.

Fast Response: This kind of valve has fast opening and closing actions, which can quickly respond to changes in fluid flow or pressure and quickly complete control tasks.

Stability: The single-link control valve adopts a stable structure and design, which can maintain stable control performance under different working conditions.

Strong Adaptability: The single-link control valve can adapt to various working media and working environments, and has strong adaptability.

Adjustable: Single-link control valves usually have an adjustment function and can adjust parameters such as flow or pressure as needed.

Durability: Single-link control valves are usually made of high-temperature and corrosion-resistant materials and have a long service life.

High Efficiency: The single-link control valve has efficient control capabilities and can accurately meet the requirements of industrial processes.

Easy To Maintain: The single-link control valve is easy to disassemble, assemble and repair, and can quickly maintain and replace parts.

Application

The single control valve, also known as an excavator, can be used in the hydraulic system of construction machinery such as excavators to achieve precise control of various actions, such as arm control, walking control, bucket control, etc.

WHY CHOOSE US

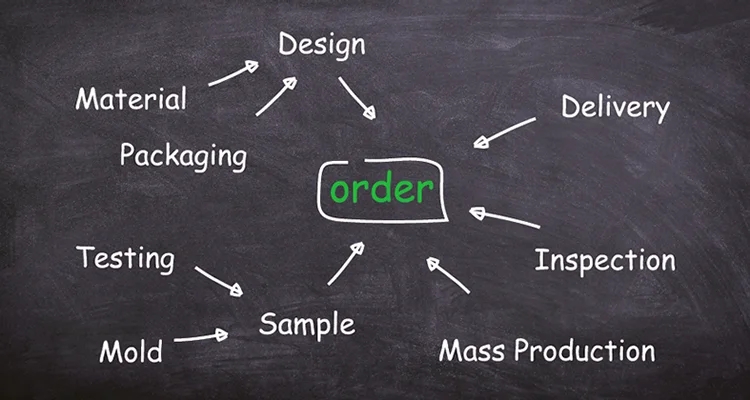

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

Quality Control

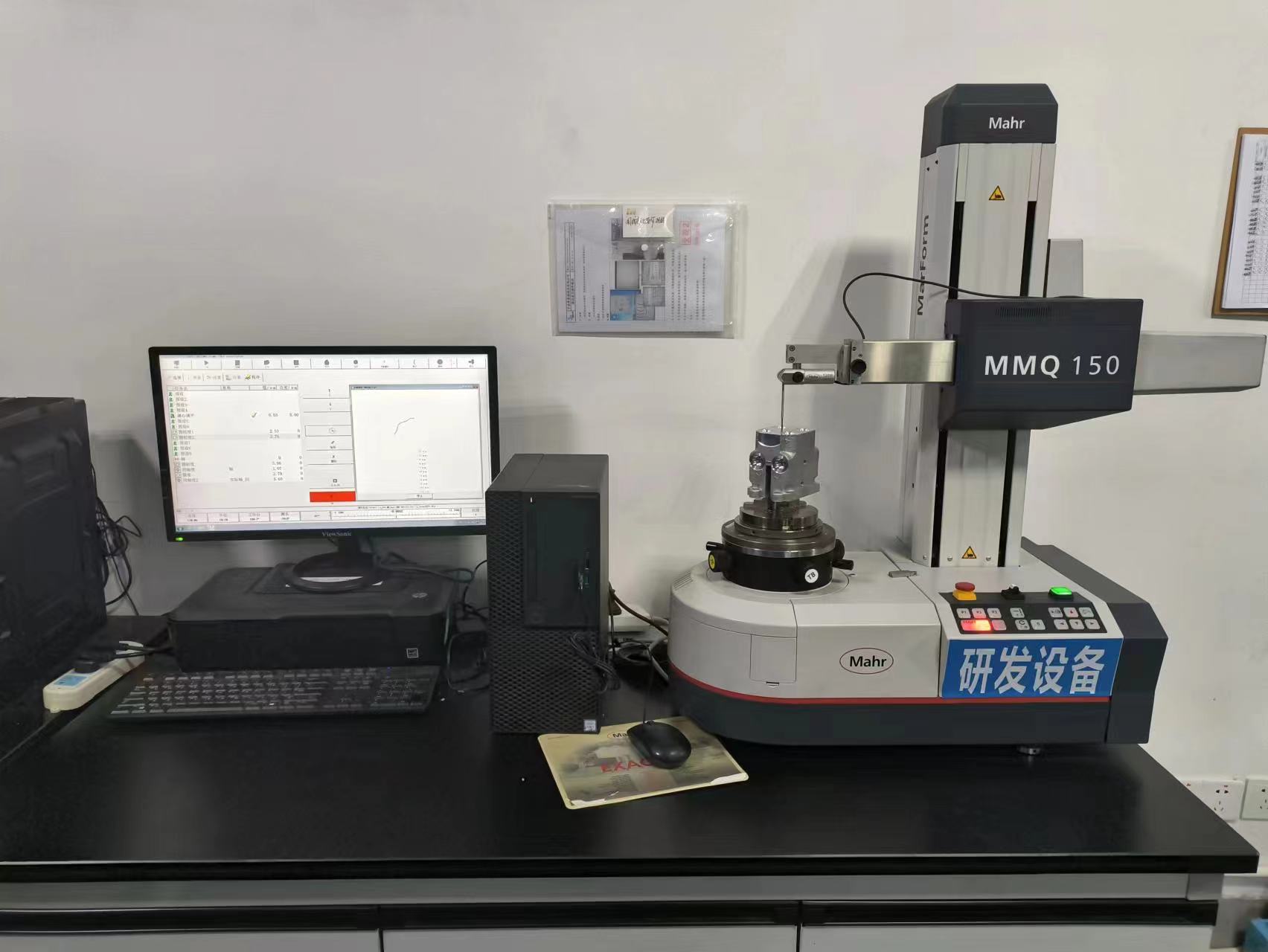

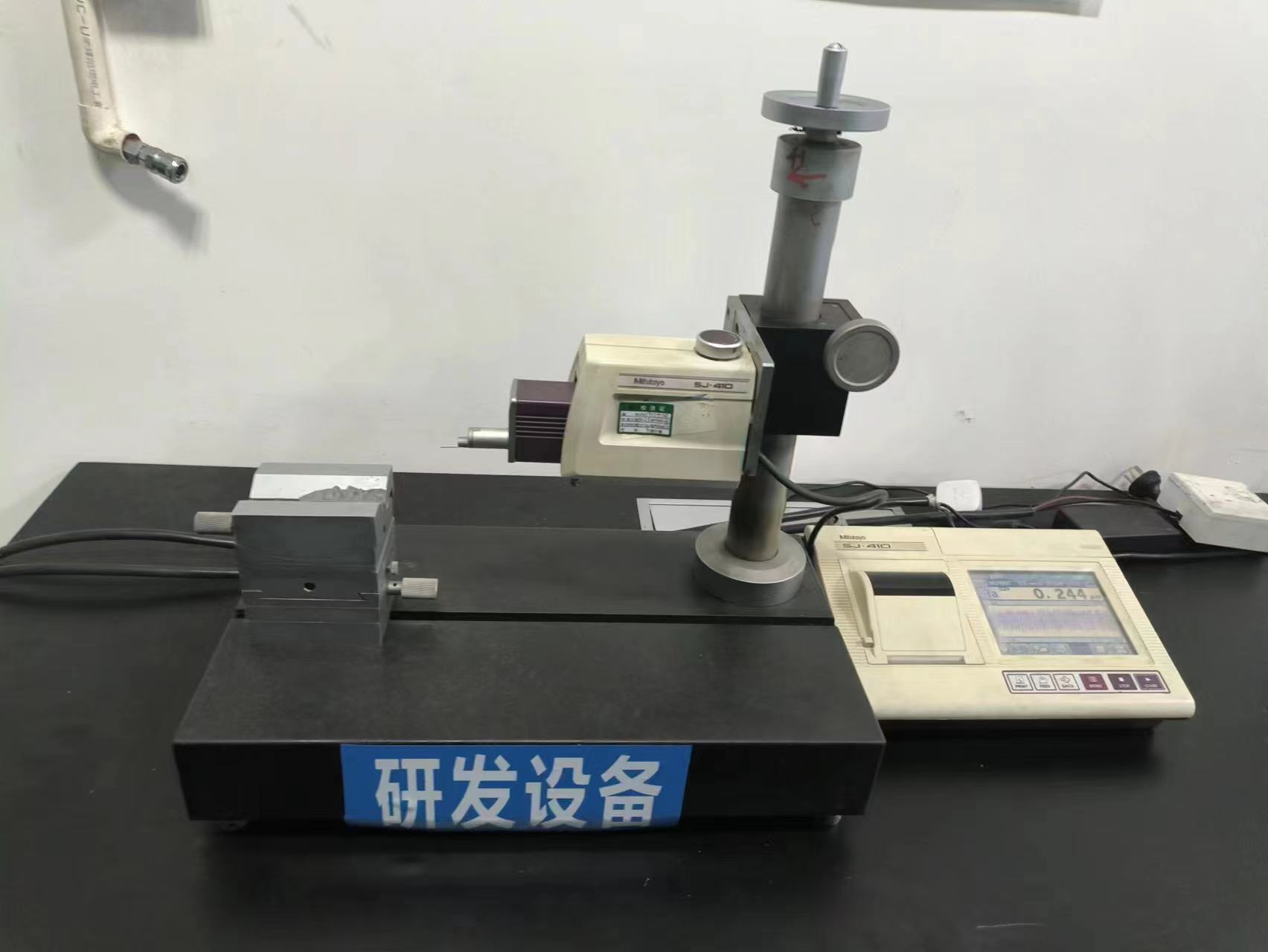

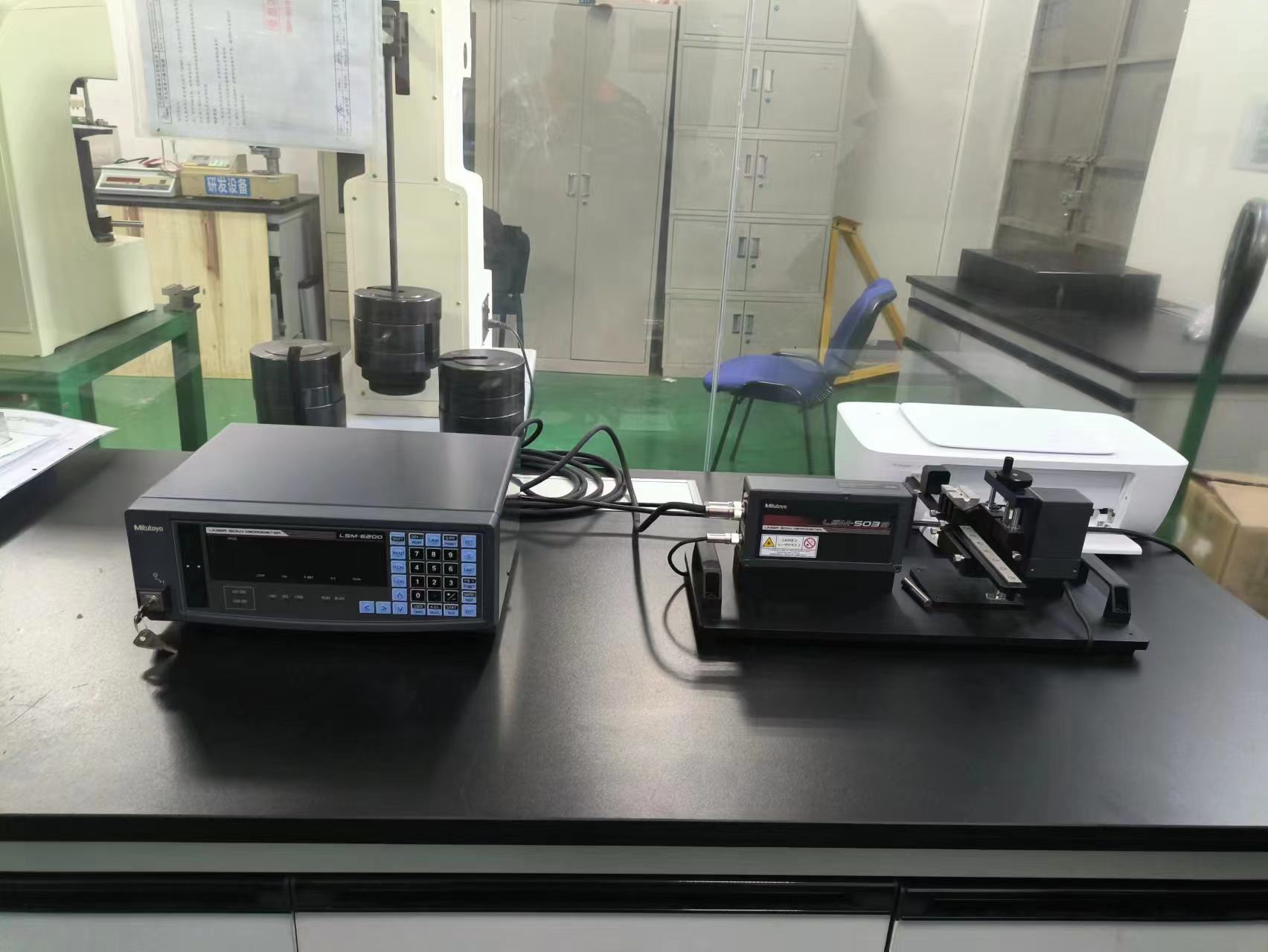

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.

-

FPJ-C4-1-E1 Drawing

FPJ-C4-1-E1 Drawing