WHO WE ARE

Ningbo Flag Hydraulic Co., Ltd. is a leading manufacturer of hydraulic components and parts, specializing in pilot control valve, hydraulic joystick control valve, plug-in overflow valve, and winches. Established in April 2010, the company is located in Ningbo, on the coast of the East China Sea, covering an area of 20,000 square meters. The company is situated in Ningbo Wangchun Industrial Park, Zhejiang Provincial Industrial Park, which is known for its advanced manufacturing facilities and technology.

The company takes pride in its innovative design and lean manufacturing processes. It has set a goal of becoming a benchmark enterprise for core parts and components in China's equipment industry through continuous innovation and development. Since its establishment, Ningbo Flag Hydraulic Co., Ltd. has been committed to the corporate culture of "people-oriented and never forgetting the original intention". The company has implemented a business policy of seeking survival by quality, development by innovation, and efficiency by management.

WHAT WE DO

In addition to pilot control valves, Ningbo Flag Hydraulic Co., Ltd. also manufactures joystick hydraulic valve that are essential for regulating the flow of hydraulic fluid to specific sections of the hydraulic system. These valves are designed with ergonomic handles for easy operation, providing users with the ability to control the movement and direction of hydraulic machinery with precision and ease. The company's joystick hydraulic valve are known for their reliability and durability, making them suitable for demanding applications in various industries.

Furthermore, Ningbo Flag Hydraulic Co., Ltd. offers cartridge valves that are designed to connect and disconnect hydraulic lines quickly and efficiently. These valves are essential for enabling the installation and removal of hydraulic components without the need for extensive disassembly of the hydraulic system. The company's plug-in overflow valve is engineered to provide leak-free connections and easy maintenance, making them an ideal choice for hydraulic systems that require frequent component replacement or reconfiguration.

Moreover, the company's winches are designed to provide powerful and reliable lifting and pulling capabilities for a wide range of applications. Whether used in construction, mining, marine, or industrial settings, Ningbo Flag Hydraulic Co., Ltd.'s marine towing winch is built to withstand rugged conditions and heavy loads. The company's winches are engineered with precision and strength, ensuring optimal performance and safety in challenging environments.

WHY CHOOSE US

EXPERIENCED

QUALITY

R&D

We have more than 15 years of experience in this item.

Introduce well-known brand processing equipment and provide QC reports.

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

OUR CERTIFICATES

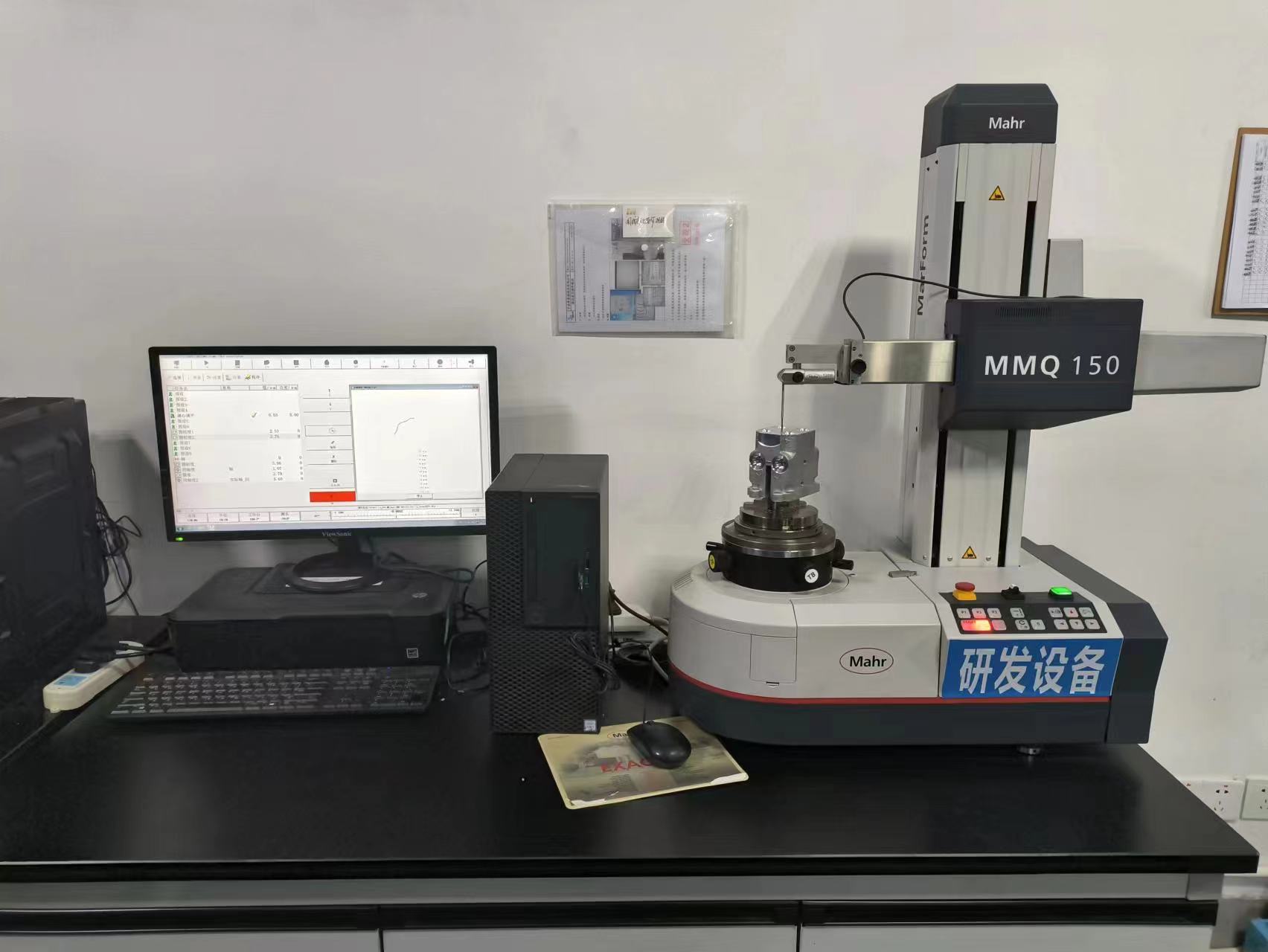

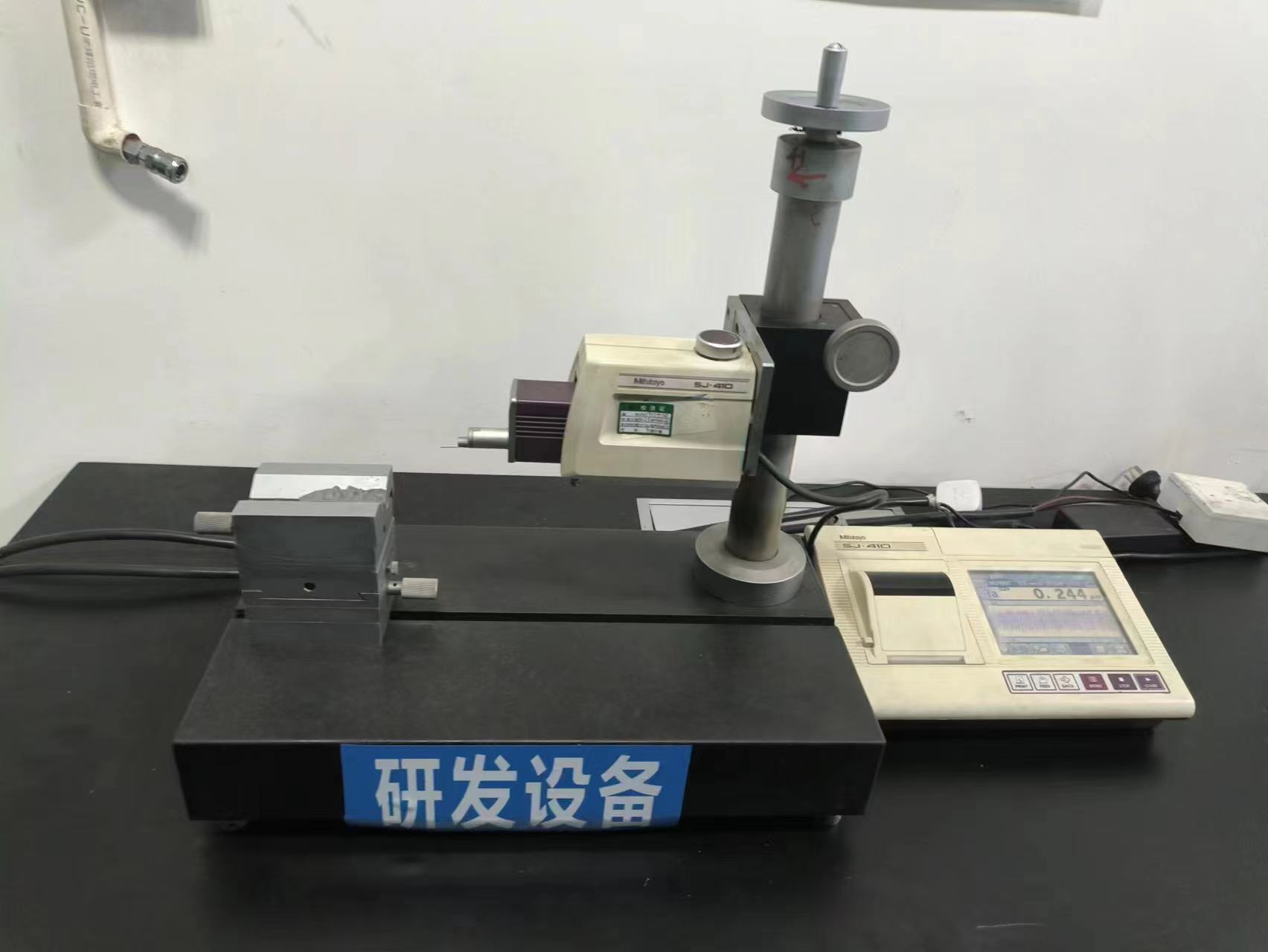

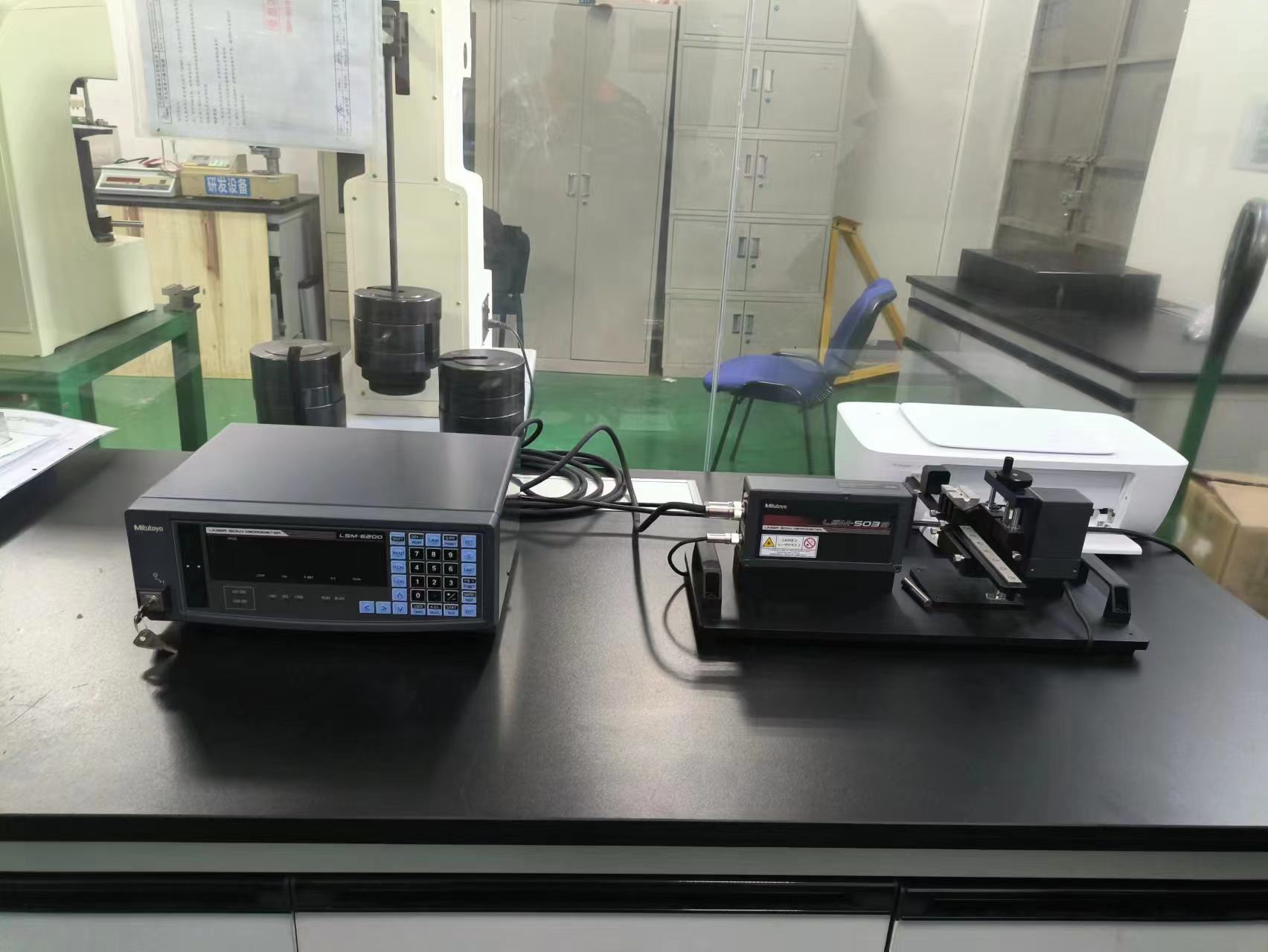

Quality Control Equipment

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.

OUR PARTNER

Over the past decade,as a trusted supplier, Ningbo Flag Hydraulic Co., Ltd. provides supporting equipment for large and powerful domestic enterprises such as Sunward Intelligent, XCMG, Sany Heavy Industry, and Zoomlion.

Application of pilot control valve in excavators

Excavators are powerful and essential pieces of heavy equipment used in construction, digging, and earthmoving projects. The efficiency and productivity of an excavator depend on the precise control and operation by the operator. One crucial component that affects the performance of an excavator is the pilot control valve, also known as the hydraulic pilot joystick, and the excavator pilot handle. These components are responsible for translating the operator's input into precise movements of the excavator's arm, bucket, and boom.

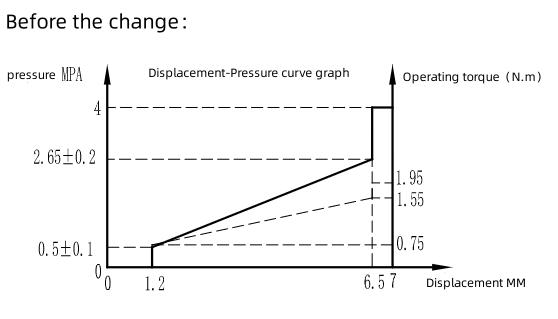

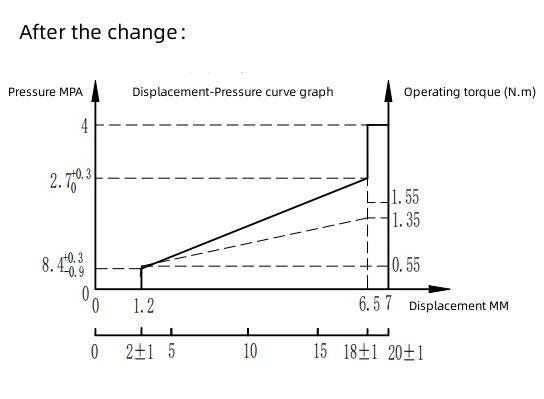

Technical feedback from XCMG customers revealed that the dead zone at the front end of the excavator was too large, and the idle stroke of the handle was too long, leading to an uncomfortable operation experience for the operators. It was evident that a redesign of the control curve based on the on-site conditions, and the multi-channel control curve provided by XCMG was necessary to address these issues and improve the overall performance of the excavator.

Our company's technology team took on the challenge to enhance the control system of the excavator by reworking the pilot control valve and excavator pilot handle to meet the specific needs of the customers. The first step was to analyze the existing control system and identify the areas that needed improvement. After careful evaluation, it was determined that adjusting the handle tripping voltage could make a significant difference in the responsiveness and ease of operation of the excavator.

The handle tripping voltage, which was originally set at (1,0.5), was modified to the current setting of (1.08) based on the redesigned control curve. This alteration aimed to reduce the dead zone and idle stroke, providing a more precise and responsive control for the operators. Once the modifications were made, the customers were invited to re-test the installation and provide their feedback on the changes.

The feedback from the customers was overwhelmingly positive, with operators expressing their satisfaction with the improved performance of the excavator. The reduction in the dead zone and idle stroke made the operation much more comfortable and efficient, allowing for more precise movements and control. The redesigned pilot control valve and handle significantly enhanced the overall user experience, leading to higher productivity and improved results on the job site.

The success of this project highlights the importance of continuously seeking feedback from customers and addressing their specific needs and concerns. By actively engaging with the end-users and incorporating their feedback into the redesign process, we were able to deliver a solution that not only met but exceeded their expectations. This collaborative approach is a testament to our commitment to customer satisfaction and continuously improving the performance of our equipment.

In conclusion, the redesign of the pilot control valve and excavator pilot handle has proven to be a game-changer in enhancing the performance of the excavator. The technical feedback from XCMG customers played a crucial role in identifying the areas for improvement, and our company's technology team rose to the challenge to deliver a solution that exceeded expectations. The success of this project serves as a testament to the value of customer feedback and the impact of innovative engineering in addressing specific needs and improving the overall performance of heavy equipment like excavators.

Among the diverse range of hydraulic components provided by Ningbo Flag Hydraulic Co., Ltd., pilot control valves play a crucial role in controlling the flow of hydraulic fluid to various actuators and motors in different applications. These valves are designed to deliver precise and proportional control of the hydraulic system, allowing for smooth and efficient operation of the machinery. The company's pilot control valves are engineered to meet the highest standards of quality and performance, making them a preferred choice for many industries.

The main types of pilot control valves produced by our company include joystick hydraulic valve, foot pedal hydraulic valve and so on.

The crane pilot control valve consists of a handle, valve body, valve core, and hydraulic control system. Its main function is to convert mechanical handle instructions into hydraulic signals, which then control the hydraulic cylinder or motor through the hydraulic control system. By using a two-way control valve design, this hydraulic loader joystick valve enables seamless control in four directions – front, rear, left, and right. Operators can effortlessly maneuver the crane by simply pushing, pulling, or shaking the handle to open or close the fluid path, effectively controlling the hydraulic system’s movement.

One of the outstanding features of this hydraulic joystick control valve is its flexibility in controlling various crane motions. Whether it’s lifting heavy loads, lowering materials, or executing precise swinging maneuvers, the crane hydraulic joystick control valve can meet the specific requirements with ease. Its hydraulic transmission ensures stable power output, enhancing the crane’s stability and safety during operation.

hydraulic foot control valve is a mechanical foot valve commonly used to control certain functions in hydraulic systems, such as cutting off flow or changing flow direction. The basic working principle of a hydraulic foot pedal valve is to control the opening and closing of the valve by stepping or releasing the foot pedal. When the foot pedal is pressed, the hydraulic pedal valve opens and allows liquid to flow through the valve; When the foot pedal is released, the valve closes, cutting off the flow of liquid.

Hydraulic pedal valve main characteristics are:

Easy To Operate: foot operated hydraulic valve can be operated by foot to control the opening and closing of the valve.

Flexibility: Foot pedal hydraulic valve is usually bidirectional and can be opened or closed by foot. Some designs can also achieve varying degrees of valve opening by adjusting the stroke and strength of the pedal.

Reliability: Single section bottom valves are usually made of wear-resistant and high-pressure resistant materials, capable of withstanding hydraulic or pneumatic pressure in the system and maintaining a stable sealing effect. Long service life and stable performance.

Welcome to contact us for more product details and we will provide quote & solution within 12 hours!