Oil source valve block – hydraulic components

Details

The oil source valve block is an important component in the hydraulic system and is mainly used to control the oil inlet and outlet of the hydraulic system. It usually includes the following components: Filter: The filter is used to filter the oil entering the hydraulic system, prevent impurities and pollutants from entering the oil source valve block and other key components, and maintain the reliable operation of the system. Main oil tank: The main oil tank is a container that stores hydraulic oil through which it is introduced into the hydraulic system. Hydraulic pump: The hydraulic pump is responsible for sucking oil from the main tank and increasing its pressure to meet the requirements of the system. Common hydraulic pump types include gear pumps, plunger pumps, and screw pumps. Oil supply pipeline: The oil supply pipeline guides the high-pressure oil output from the hydraulic pump to various components of the system, such as hydraulic cylinders, hydraulic motors, etc., to promote and drive mechanical movement. Relief Valve: Relief valve is used to control and regulate the pressure of the system. When the system pressure exceeds the set value, the relief valve will open to release excess oil to maintain the stable working condition of the system. Directional valve: The direction valve is used to control the flow direction of hydraulic oil in the hydraulic system to achieve motion control and direction switching of different working strokes. The design and configuration of the oil source valve block will vary based on the specific requirements and application scenarios of the hydraulic system. Its main function is to provide a stable oil source and control and regulate the hydraulic oil through the control valve. At the same time, the oil source valve block also needs to have certain maintainability and reliability to ensure the normal operation of the hydraulic system.

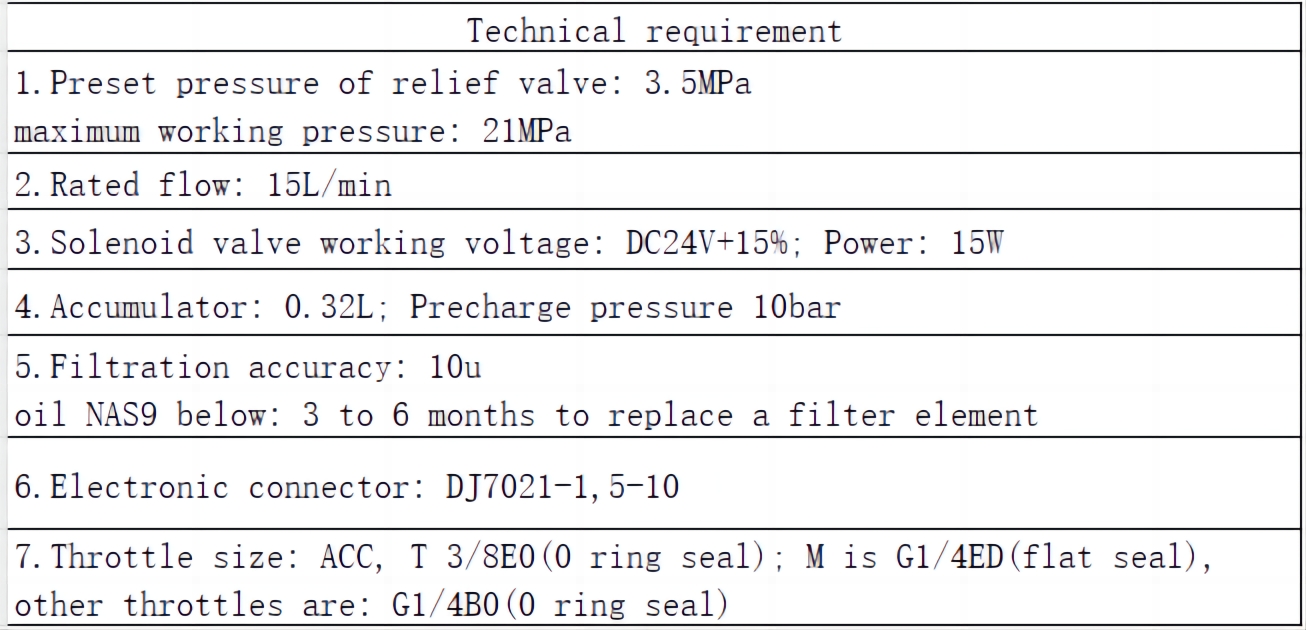

Product Specifications

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

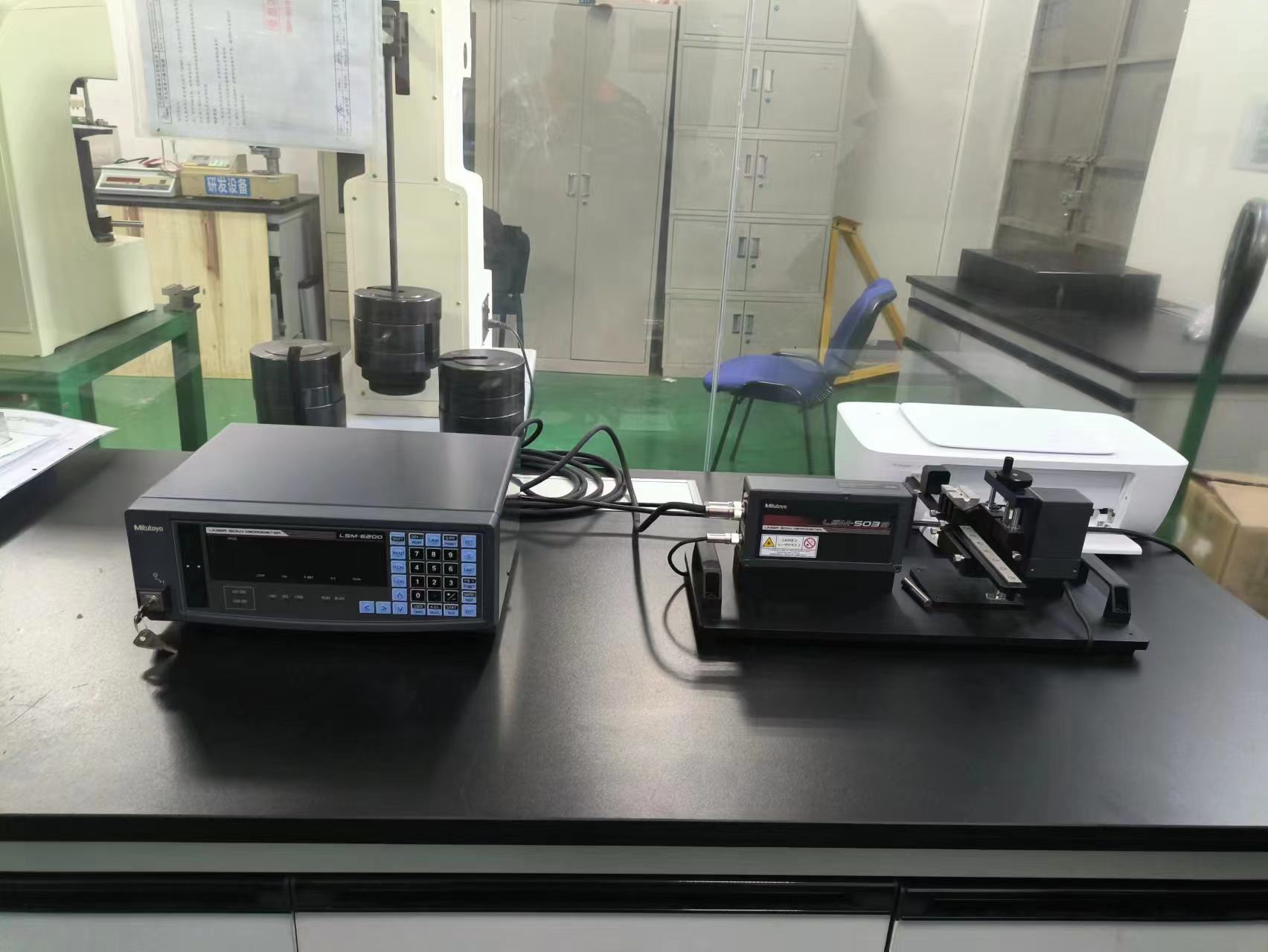

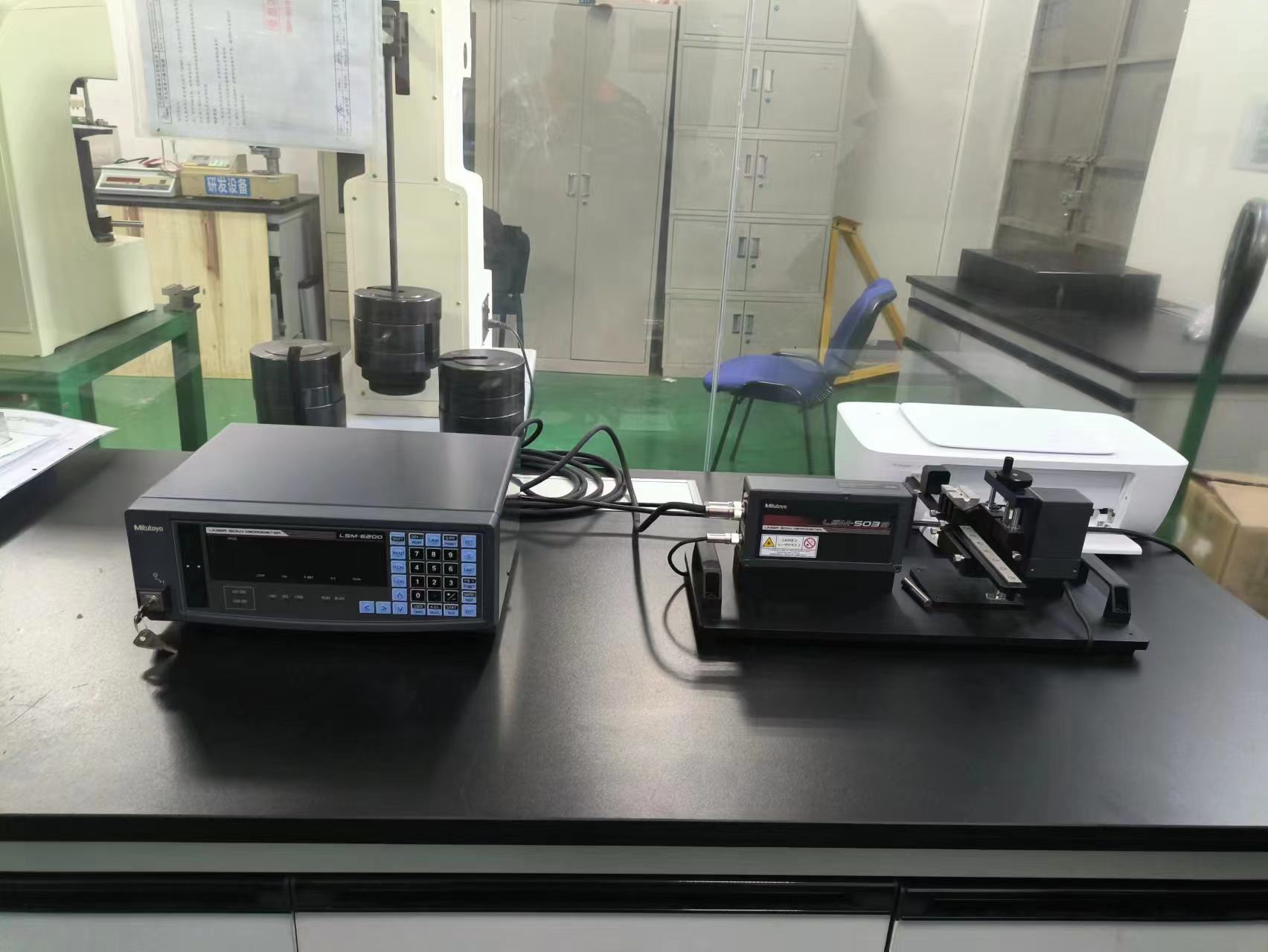

Quality Control

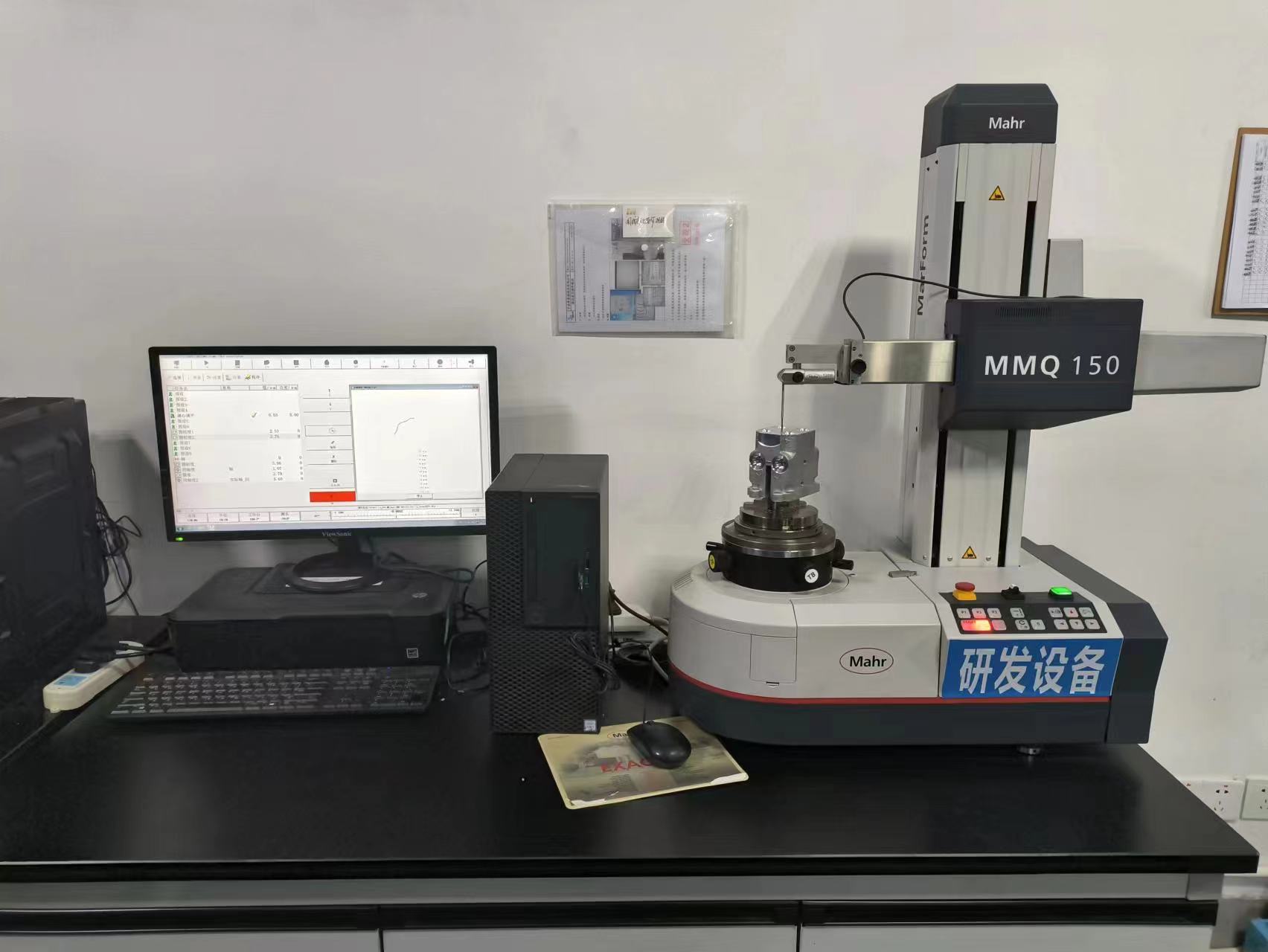

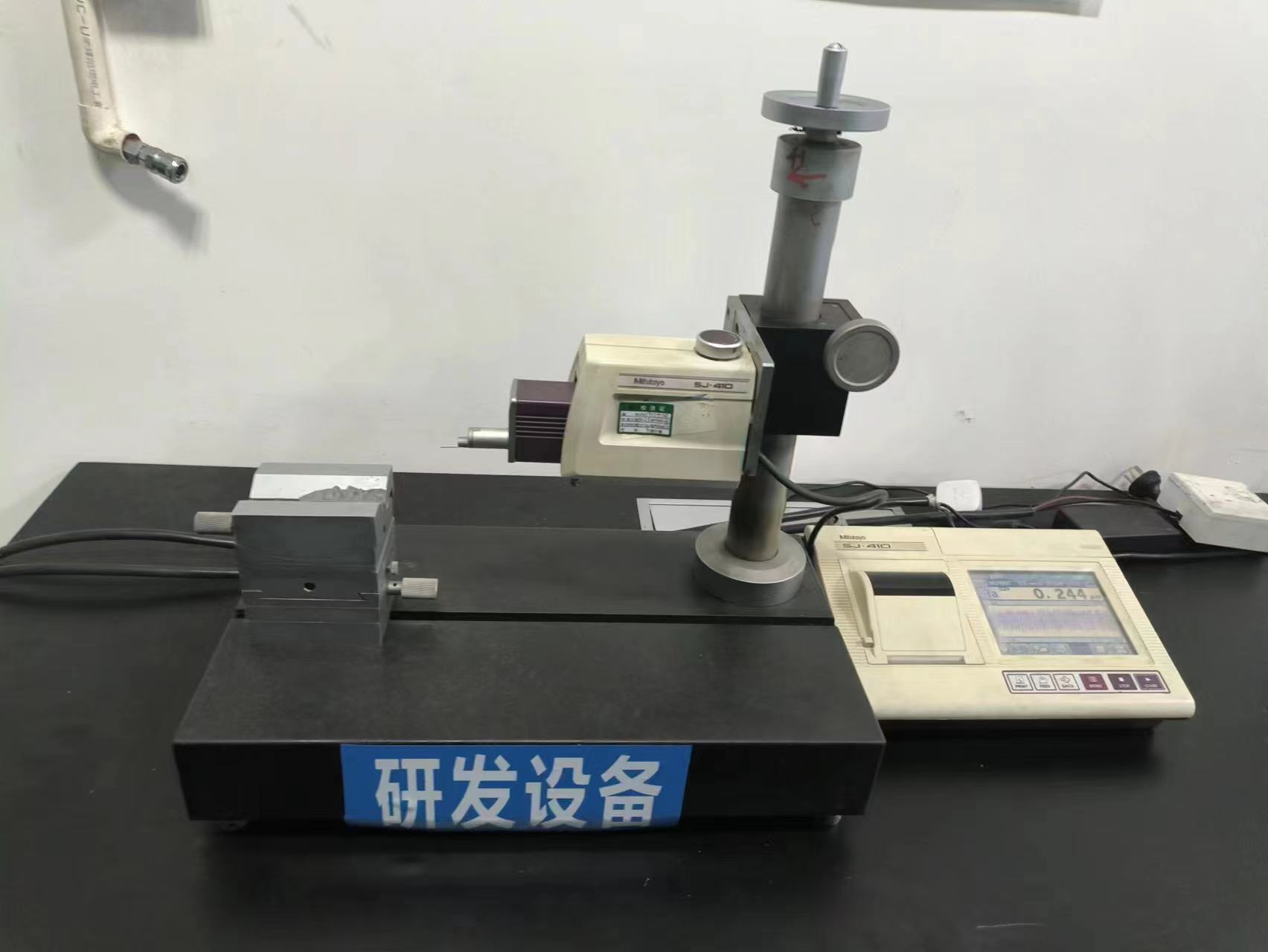

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

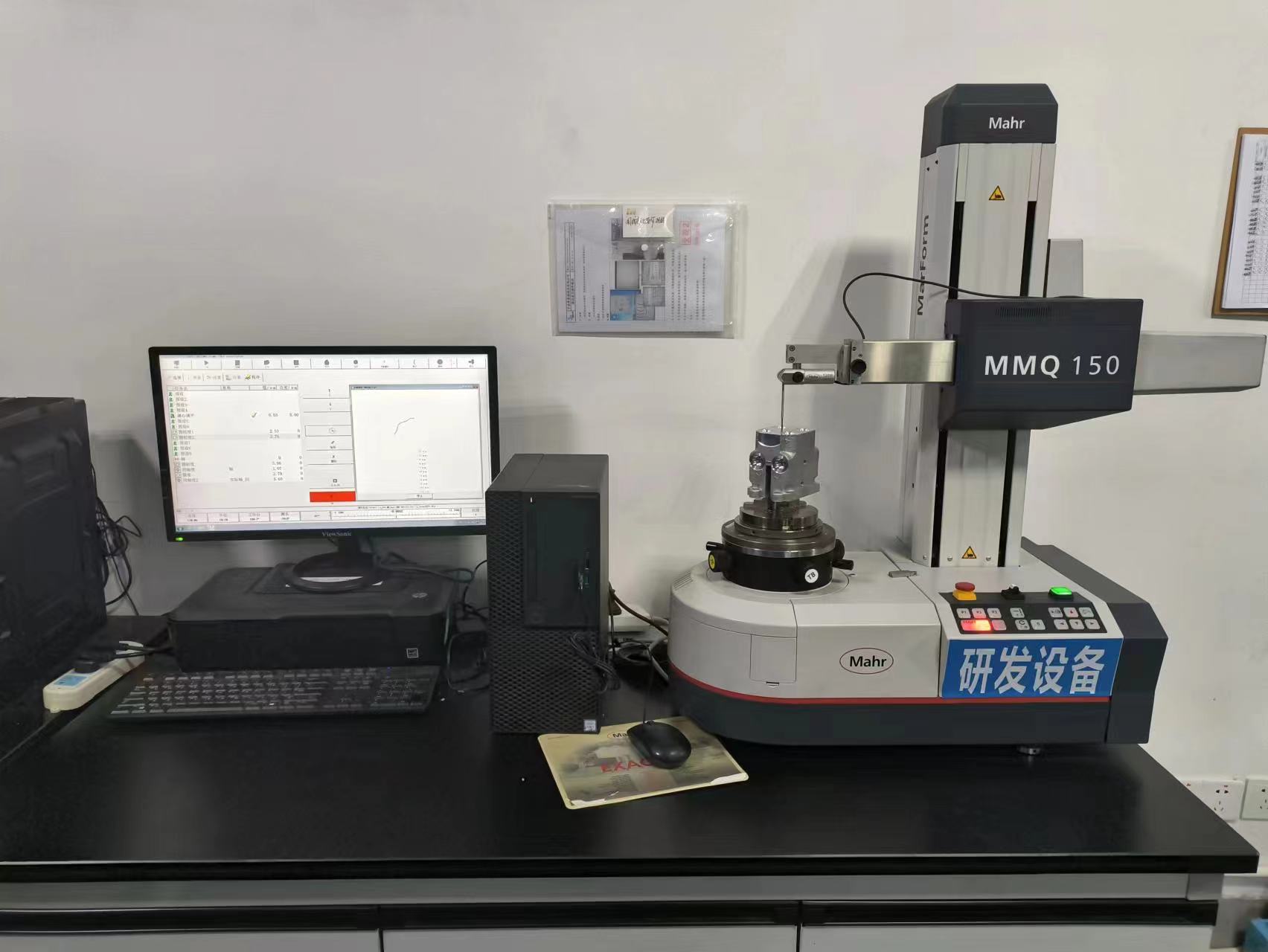

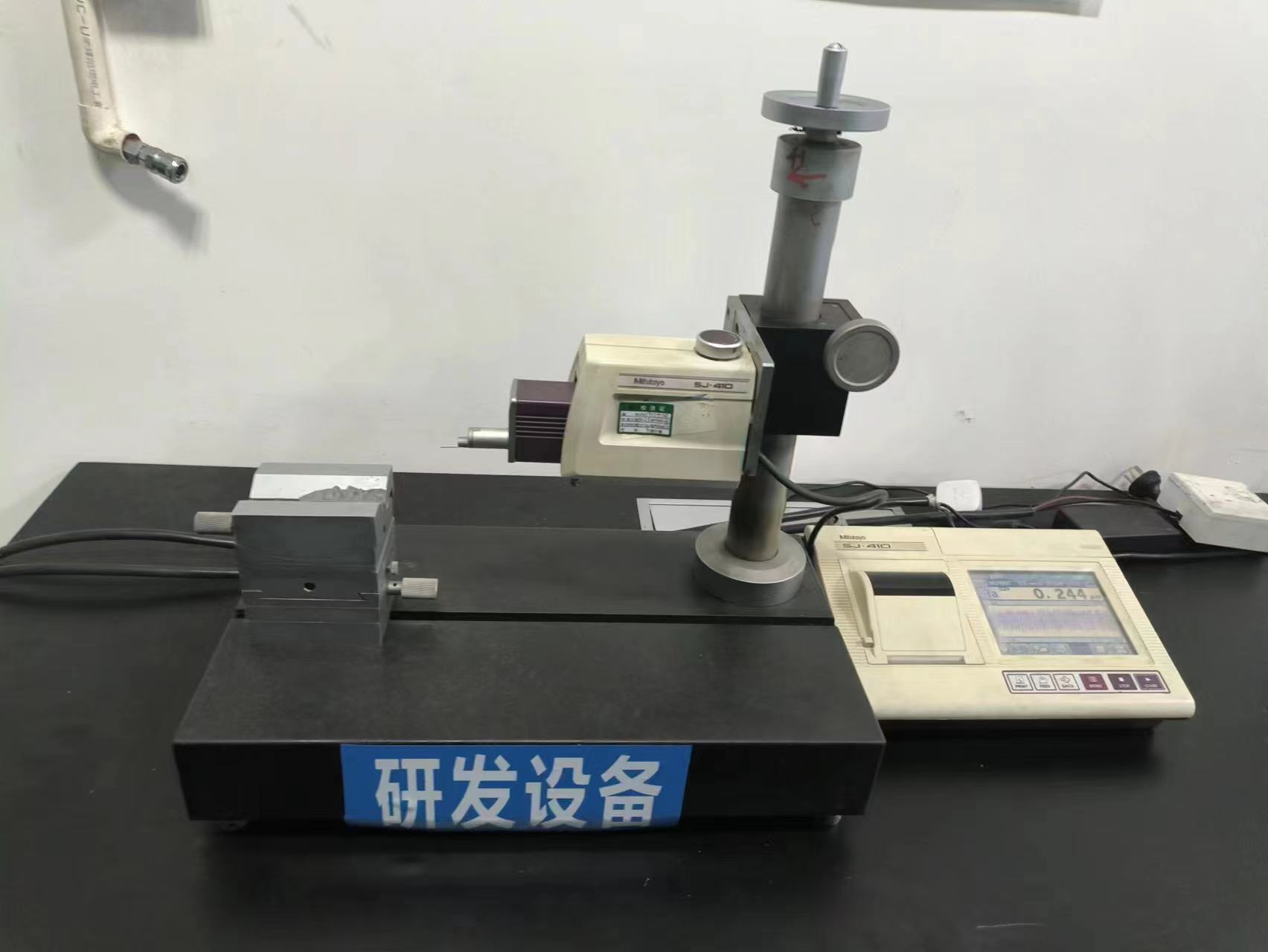

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

Quality Control

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.

-

811300096

811300096 -

811300220

811300220 -

811300221

811300221 -

811300245

811300245