Multiple pilot operated valve

Details

The function description of the Multiple pilot operated valve produced by Ningbo Falgup Hydraulic Co., Ltd.: The human moves the rod downward by changing the angle of the handle and shaking the swing block, while the valve core moves downward under the action of external force. The reset spring begins to compress until the working port and pressure oil port P are connected. As the pressure at the working port increases, the force acting on the valve core needs to achieve force balance with the pressure reducing spring, Thus achieving a proportional decompression effect. The output pressure of the working port is directly proportional to the working angle of the handle.

If you have any more specific questions or need to know about a specific model of multi-pilot valve products, please feel free to let me know, and I will try my best to provide more detailed help and information.

Multiple pilot operated valve is a valve used in hydraulic systems with the following characteristics: Multi-function: The multi-link operating valve can realize a variety of hydraulic functions, such as flow control, pressure control, direction control, etc., and is suitable for different hydraulic system applications. High reliability: The multi-link operating valve adopts high-quality materials and manufacturing processes, has good sealing and durability, can work stably for a long time, and reduces the number of failures and repairs. Flexibility: Multi-link operating valves can be configured and combined according to actual needs to adapt to different hydraulic system layouts and application requirements. Precise control: The multi-link operating valve has precise control capabilities, which can achieve accurate operation of each hydraulic component in the hydraulic system and improve work accuracy and efficiency. Safety: The multi-link operating valve adopts reliable safety valves, relief valves and other protection devices, which can function in time under abnormal system conditions and protect the safety of the hydraulic system and equipment. Easy to install and maintain: The multi-operated valve adopts a modular design, which makes installation easy and fast, and maintenance and replacement of parts are also relatively simple. In general, multi-link operating valves can meet the needs of different hydraulic systems due to their multi-function, reliability and flexibility, and are widely used in engineering machinery, agricultural machinery, ships and other industries.

Application

Multiple control valves can be used in the hydraulic systems of construction machinery such as excavators, loaders, bulldozers, cranes, etc., to achieve precise control of various actions, such as arm control, walking control, bucket control, etc.

Product Operation Symbol

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

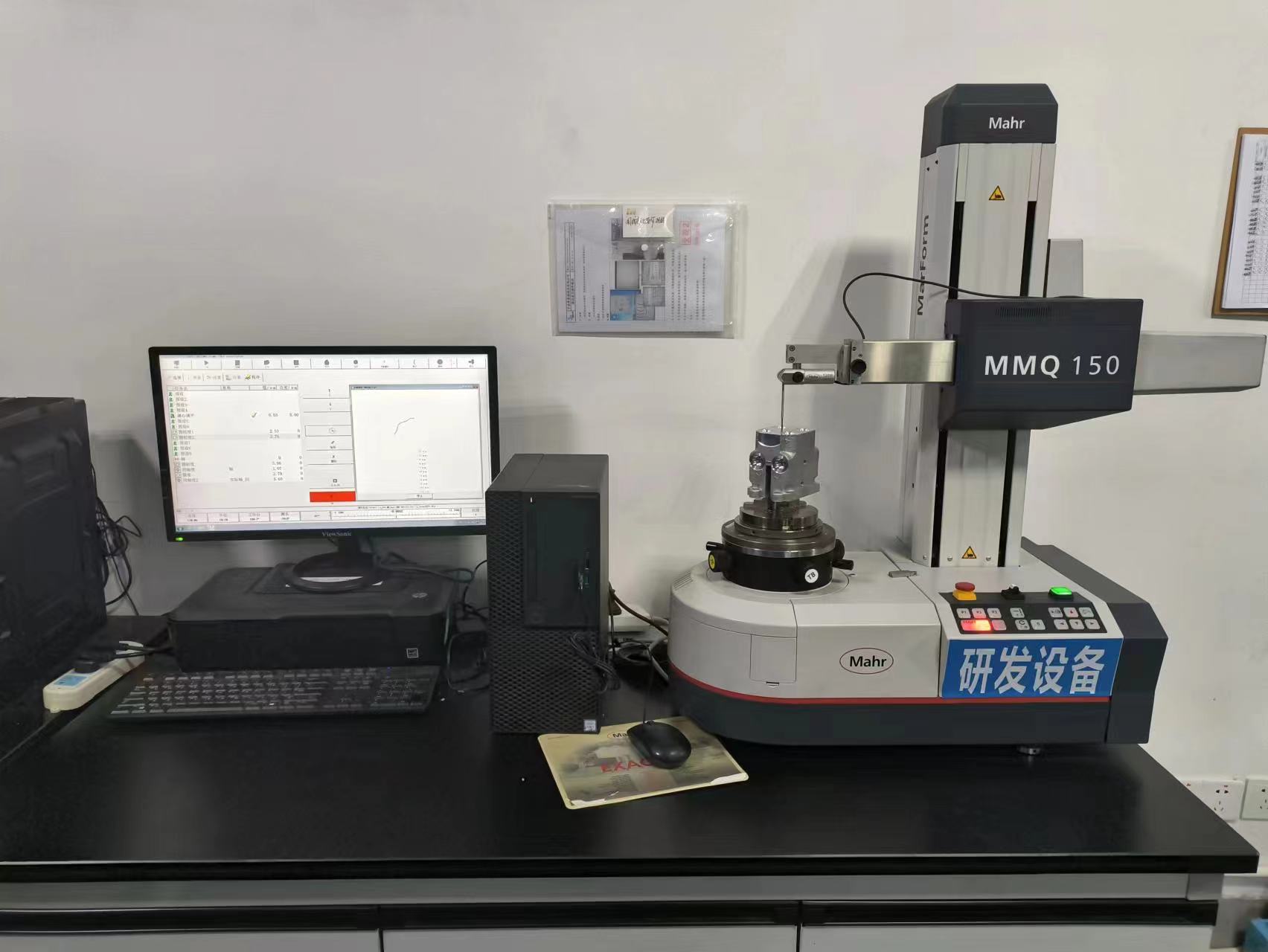

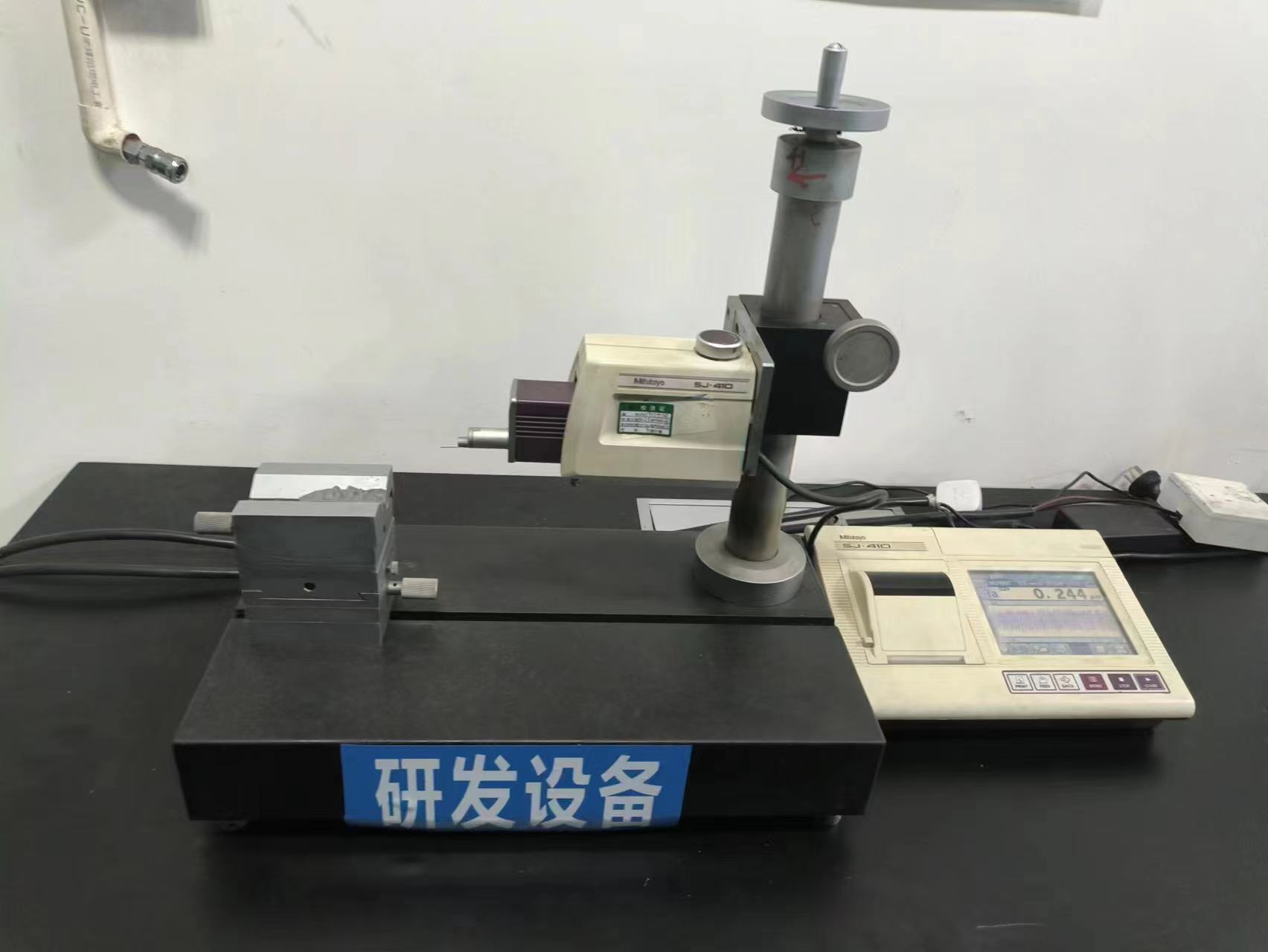

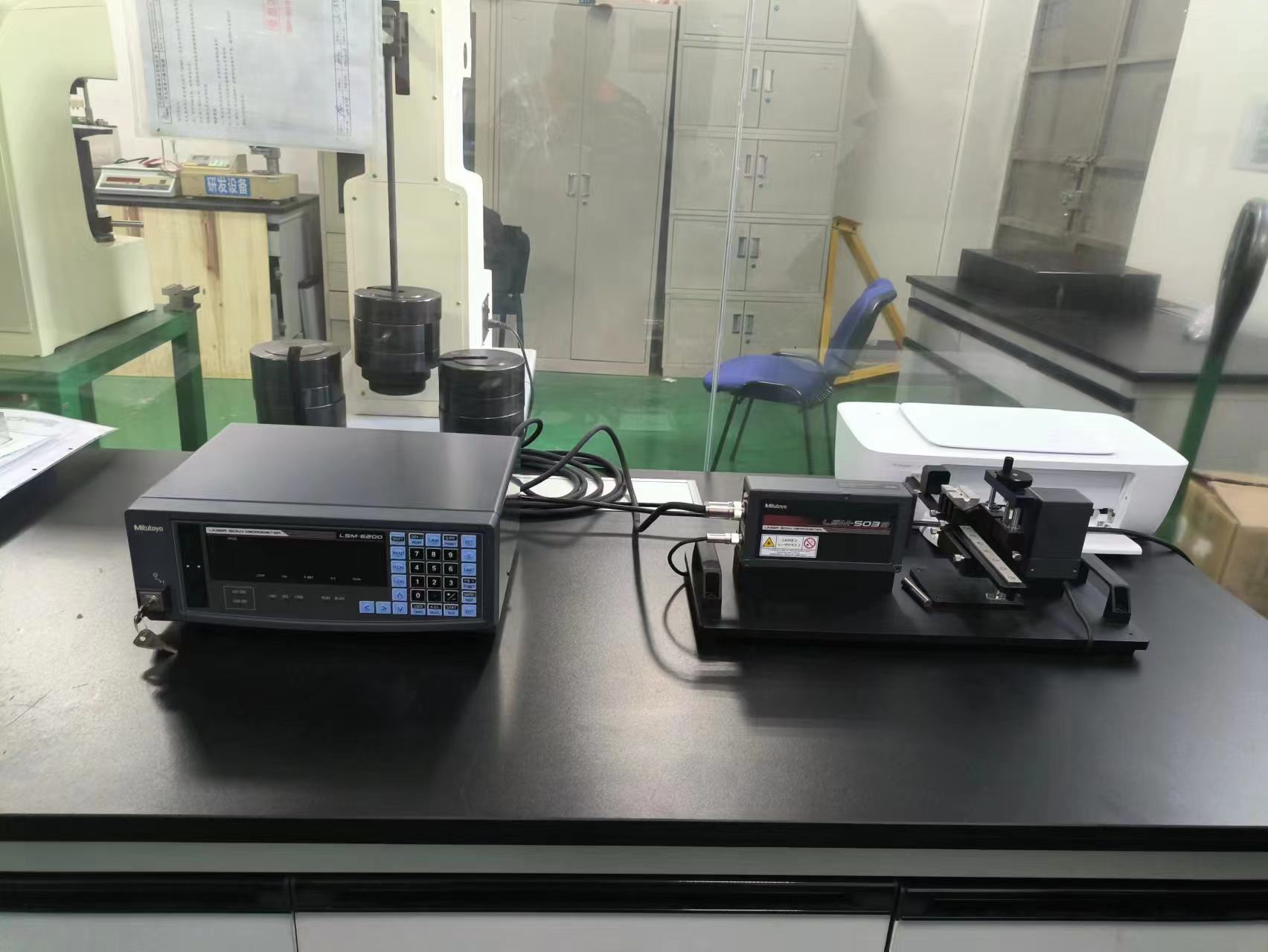

Quality Control

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.

-

FPJ-C5-0-E5 Drawing

FPJ-C5-0-E5 Drawing