MS05 Hydraulic Motor

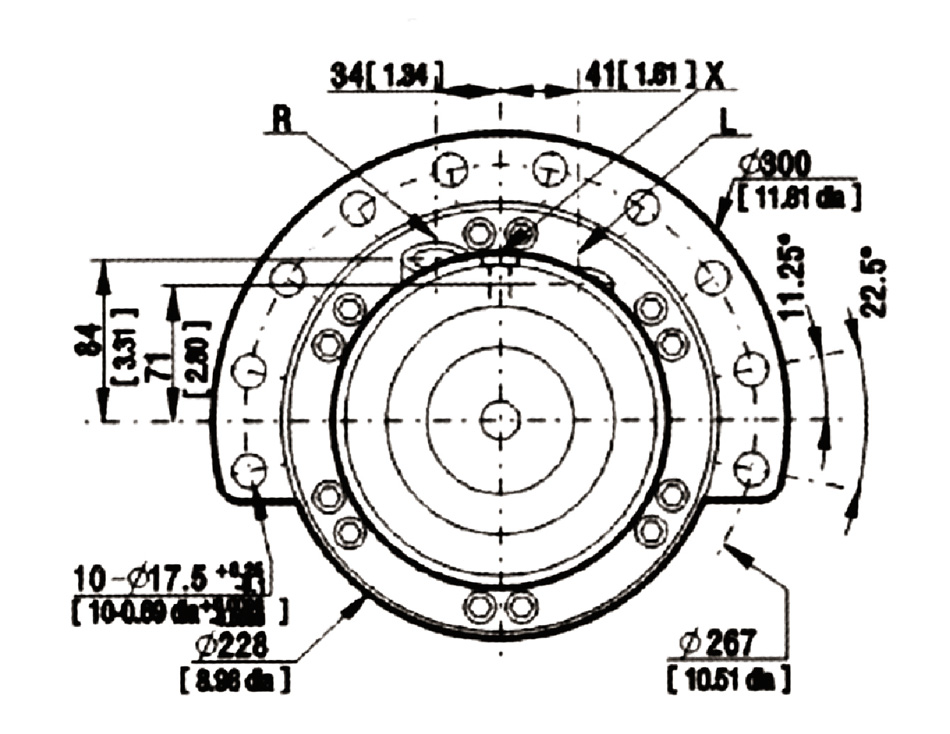

Displacement diagram

| Code | MS05 | ||||

| Displacement group | 6 | 8 | 0 | 1 | 2 |

| Displacement(ml/r) | 260 | 376 | 468 | 514 | 560 |

| Theoreticaltorque at 10Mpa(N.m) | 413 | 598 | 744 | 817 | 890 |

| Rated speed(r/min) | 160 | 160 | 125 | 125 | 125 |

| Rated pressure(Mpa) | 25 | 25 | 25 | 25 | 25 |

| Rated torque(N.m) | 850 | 1200 | 1500 | 1650 | 1800 |

| Max.pressure(Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 |

| Max.torque(N.m) | 1050 | 1500 | 1850 | 2050 | 2250 |

| Speed range(r/min) | 0-265 | 0-250 | 0-240 | 0-220 | 0-200 |

| Max.power(KW) |

The standard displacement is 29KW, and the variable displacement prioritizes rotating towards 19KW. Variable displacement non priority rotation direction 15KW. |

||||

Connection size diagram

MS05 Application

The product is widely used in hydraulic transmission systems of various machinery such as ship deck machinery, mining machinery, engineering machinery, metallurgical machinery, petroleum and coal mining machinery, lifting and transportation equipment, agricultural and forestry machinery, drilling rigs, etc

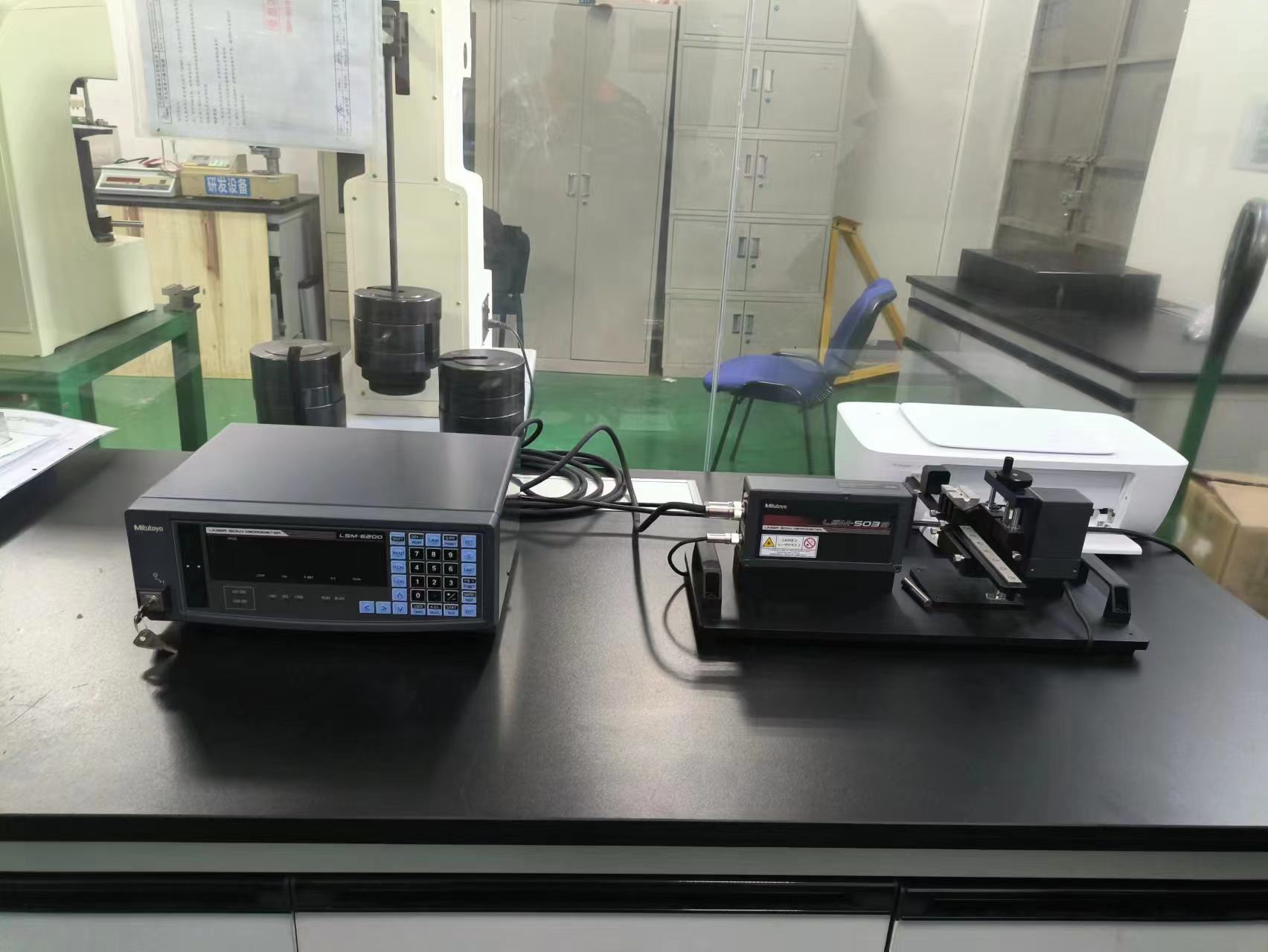

Product image

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

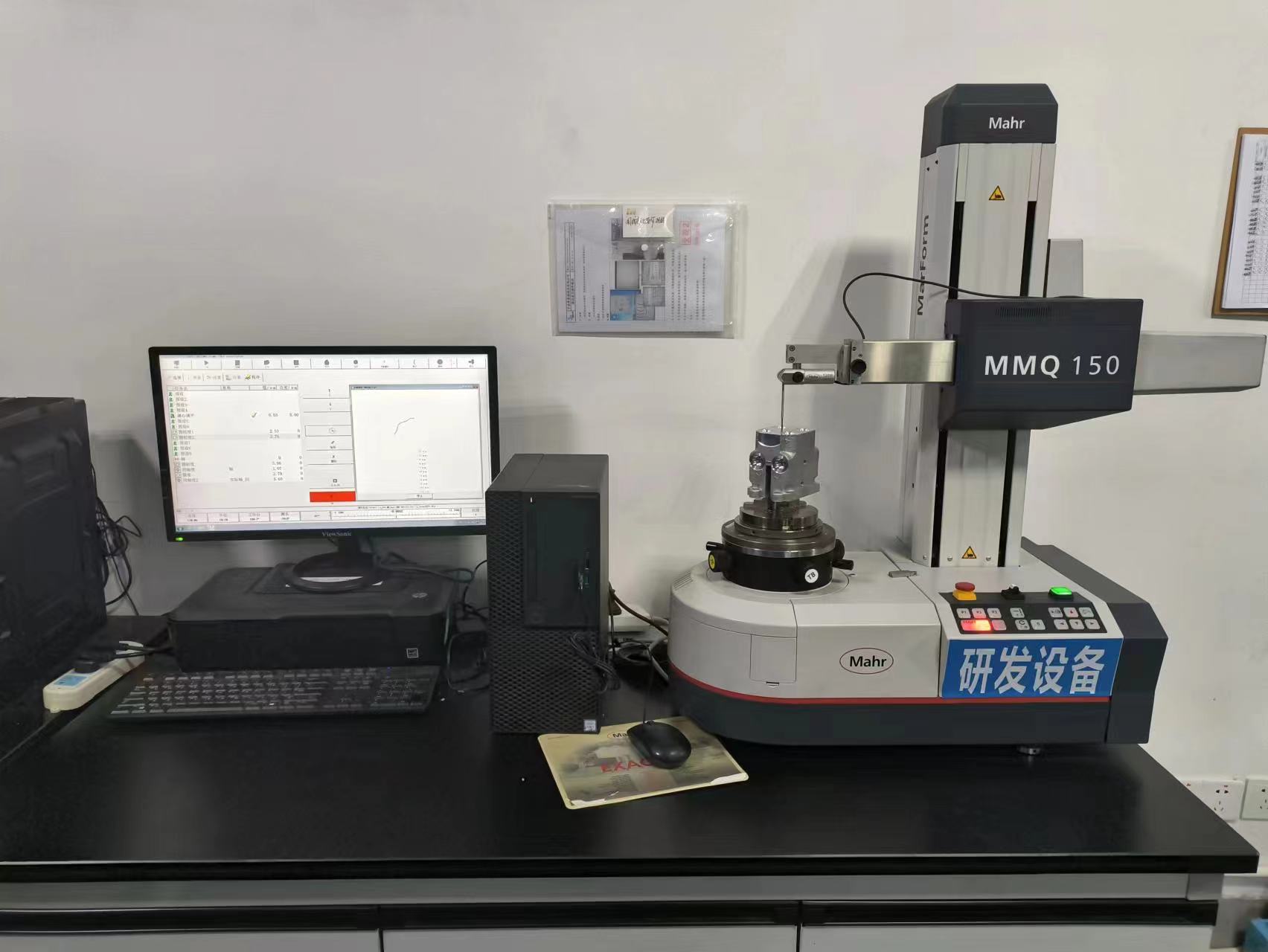

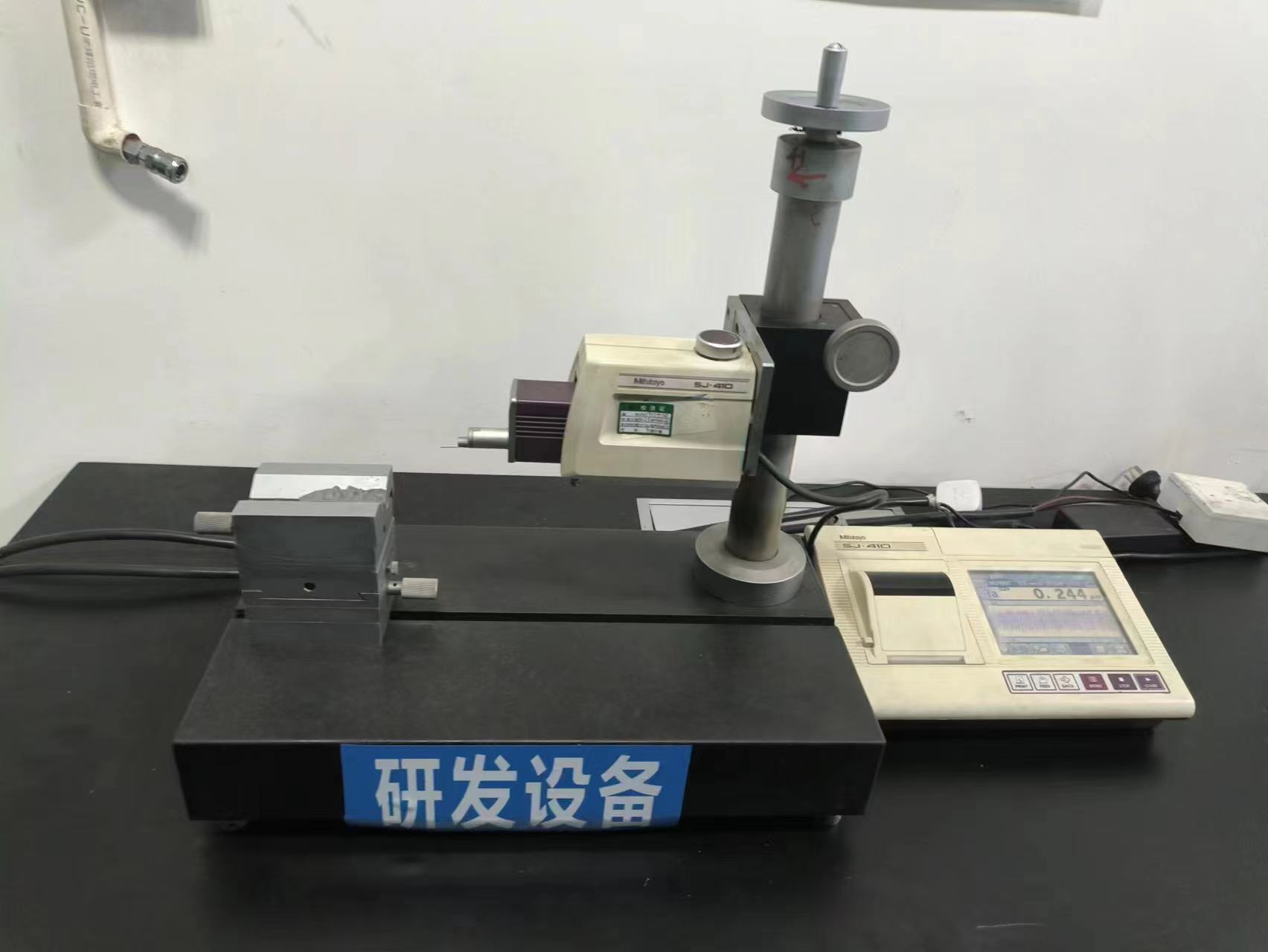

Quality Control

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.