Mining electric winch, Mining electric windlass

Product Specifications

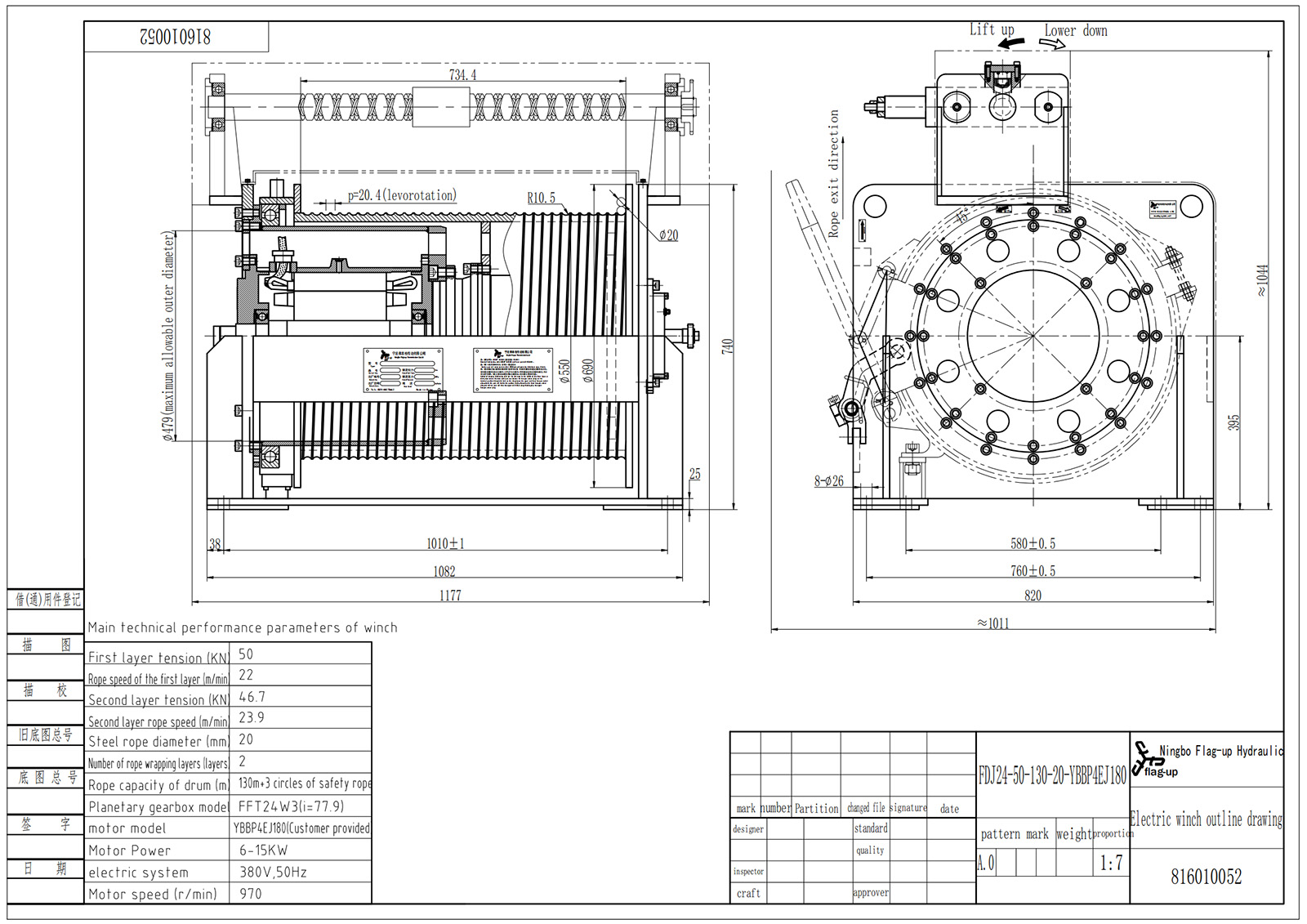

| Main technical performance parameters of winch | |

| First layer tension (KN) | 50 |

| Rope speed of the first layer (m/min) | 22 |

| Second layer tension (KN) | 46.7 |

| Second layer rope speed (m/min) | 23.9 |

| Steel rope diameter (mm) | 20 |

| Number of rope wrapping layers (layers) | 2 |

| Rope capacity of drum (m) | 130m+3 circles of safety rope |

| Planetary gearbox model | FFT24W3(i = 77.9) |

| Motor model | YBBP4EJ180(Customer provided) |

| Motor Power | 6-15KW |

| Electiric system | 380V, 50Hz |

| Motor speed (r/min) | 970 |

Product Features

Mining electric winches have the following characteristics:

High Load-bearing Capacity: Mining electric winches usually have a large rated load-bearing capacity, which can adapt to the lifting needs of heavy objects in mining operations.

Powerful Power System: It uses an electric motor as the power source and has strong power output, which can provide sufficient torque and speed to adapt to different work needs.

Efficient Work: Mining electric winches adopt a professionally designed transmission system, which has high transmission efficiency and can quickly lift and transport heavy objects, improving work efficiency.

Safe And Reliable: Mining electric winches are usually equipped with multiple safety protection devices, such as limit switches, overload protection devices, etc., to ensure the safety of equipment and operators.

Strong Durability: Mining electric winches use high-strength materials and professional manufacturing processes, which have good durability and weathering resistance, and can maintain stability and durability even in harsh mining working environments.

Application

Mining electric winches are widely used in lifting and handling work in mines, such as coal mines, metal mines, and quarries.

Drawing

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

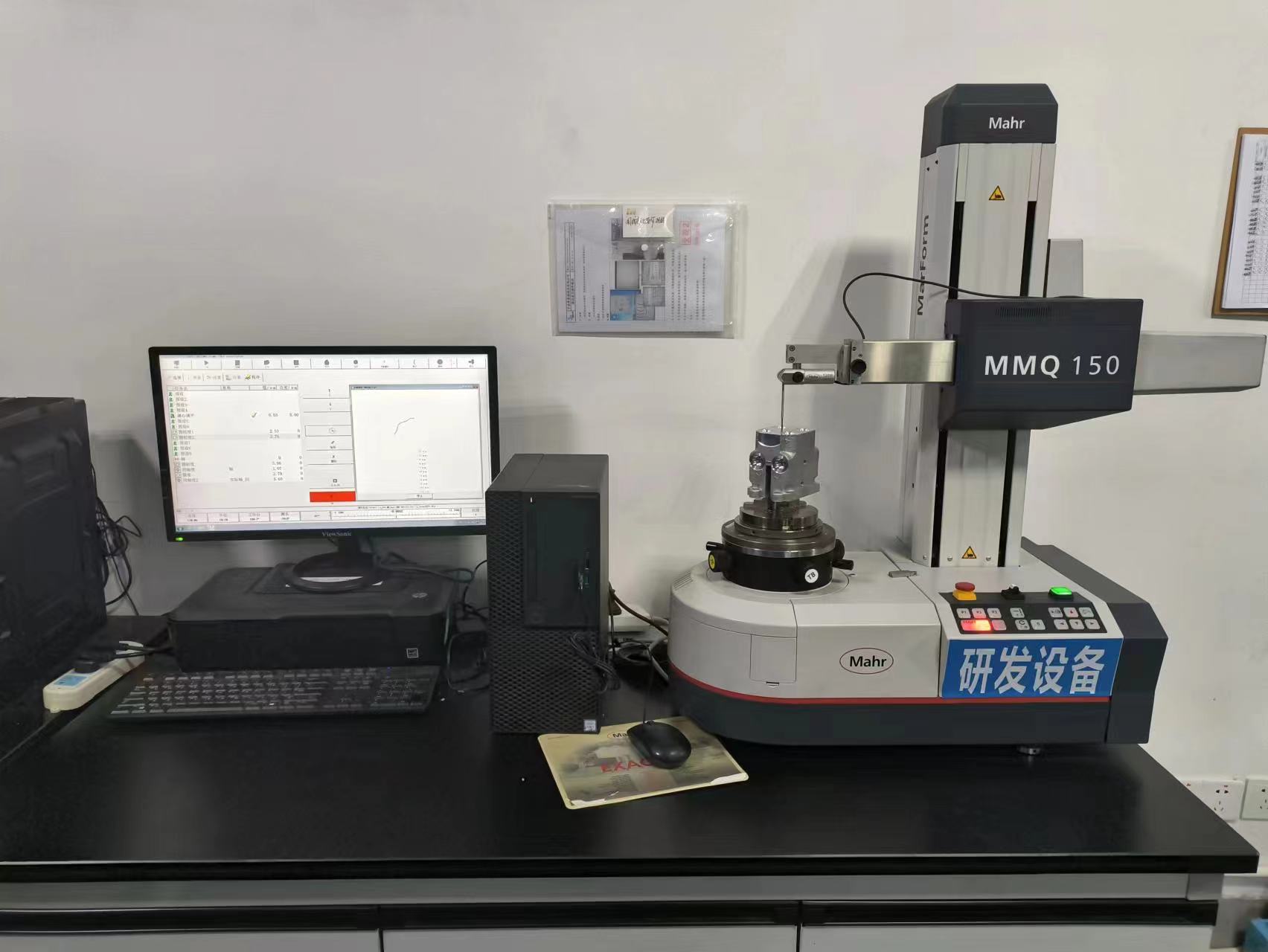

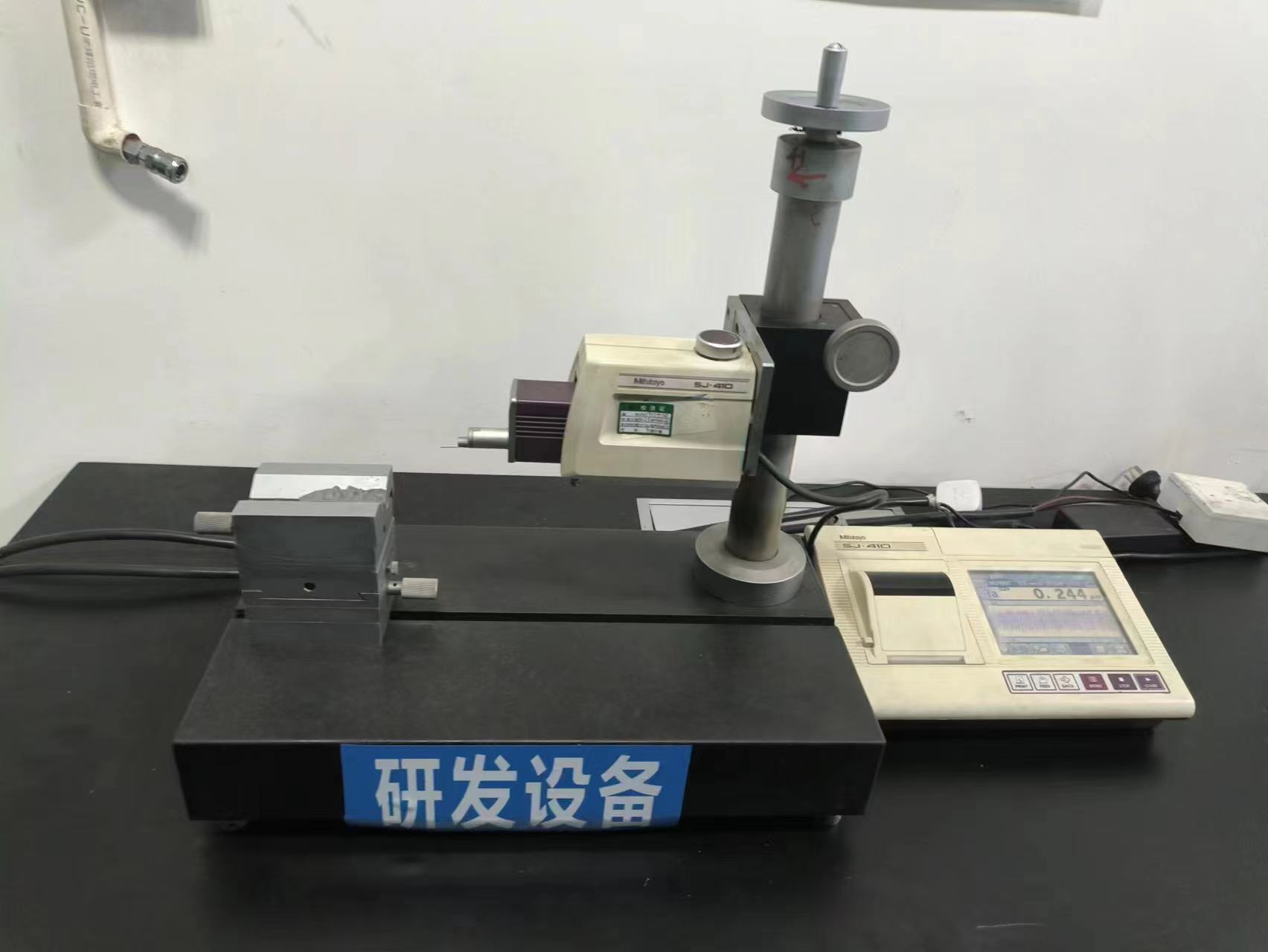

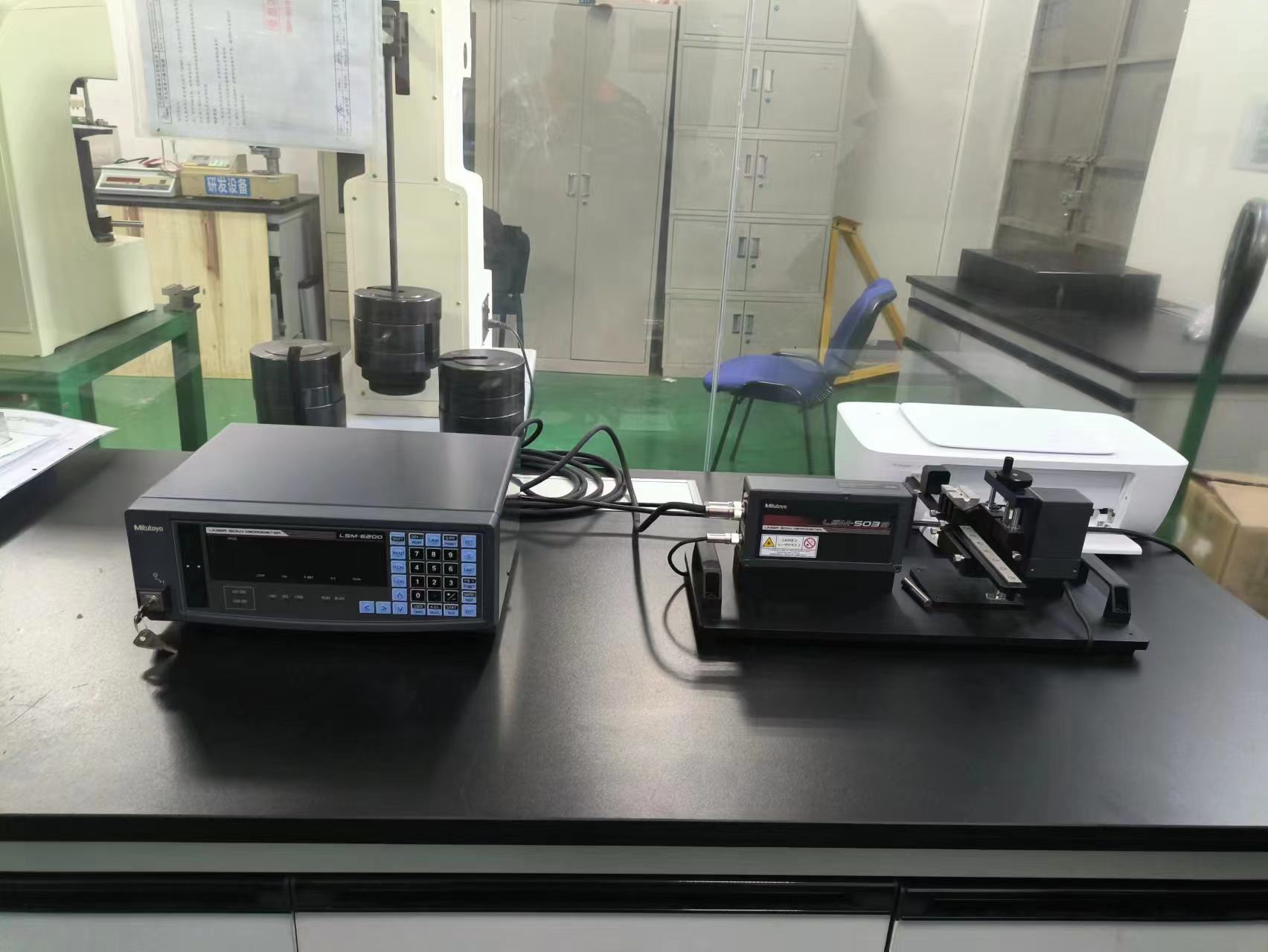

Quality Control

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.

-

Mining electric winch, Mining electric windlass

Mining electric winch, Mining electric windlass