23DH-E08 Spool 3-Way 2-Position Solenoid Valve

Product Features

1. Coil with a continuous service rating.

2. Extensively hardened precision spool and cage.

3. Coil voltages and potential endings

4. A functional wet-armature design.

5. Cartridges can be used with various voltages.

6. There may be strain on the entire system.

7. An option for manual override.

8. Optional IP69K-rated waterproof E-Coils.

9. Molded coils with a unitized design.

10. Small dimensions.

Product Specifications

| Product Model | 23DH-E08 Spool 3-Way 2-Position Solenoid Valve |

| Operating Pressure | 207 bar (3000 psi) |

| Internal Leakage | 82 ml/min. (5 cu. in./minute) max. at 207 bar (3000 psi) |

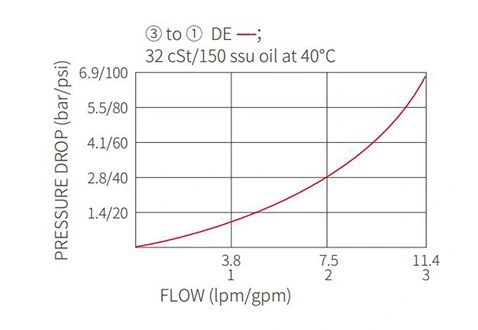

| Flow | See Performance Chart |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage |

| Temperature | -40°℃~100°C |

| Initial Coil Current Draw at 20°C | Standard Coil: 1.2 amps at 12 VDC; 0.13 amps at 115 VAC (full wave rectified). E-Coil: 1.4 amps at 12 VDC; 0.7 amps at 24 VDC |

| Minimum Pull-in Voltage | 85% of nominal at 207 bar (3000 psi) |

| Fluids | Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 ssu). |

| Installation | No restrictions |

| Cartridge | 0.13 kg. (0.28 lbs.); Steel with hardened work surfaces. Zinc-plated exposed surfaces. |

| Seal | D type seal rings |

| Standard Ported Body | Weight: 0.27 kg. (0.60 lbs.); Anodized high-strength 6061 T6 aluminum alloy, rated to 240 bar (3500 psi). Ductile iron and steel bodies available; dimensions may differ. |

| Standard Coil | Weight: 0.11 kg. (0.25 lbs.); Unitized thermoplastic encapsulated, Class H high temperature magnetwire. |

| E-Coil | Weight: 0.14 kg. (0.30 lbs.); Perfect wound, fully encapsulated with rugged external metal shell; Rated up to IP69K with integral connectors. |

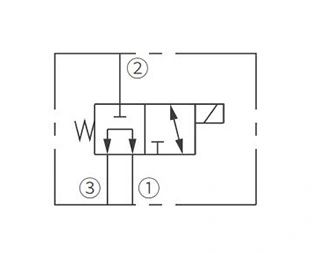

Product Operation Symbol

When de-energized, the 23DH-E08 allows flow from ③ to ①, while blocking flow at ②. When energized, the cartridge's spool shifts to open the ② to ① flow path, while blocking flow at ③.

Operation of Manual Override Option

To override, push button in, twist counterclockwise 180°, and release. The internal spring will push the button out. In this position, the valve may be only partially shifted. To assure full override shift, pull the button out to its fullest extension and hold it in this position. To return to normal operation, push button in, twist clockwise 180°, and release. Override will be detented in this position.

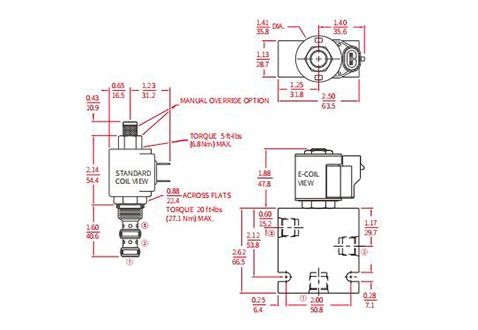

Performance/Dimension