2-position 2-way proportional flow valve 20BL-08

Product Features

1. Continuous-duty rated coils.

2. Efficient wet-armature construction.

3. Manual override options

4. Optional waterproof E-Coils rated up to IP69K.

Product Specifications

| Product Model | 2-position 2-way proportional flow valve 20BL-08 |

| Operating Pressure | 250 bar (3600 psi) |

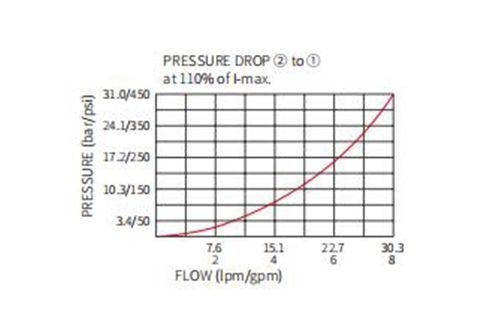

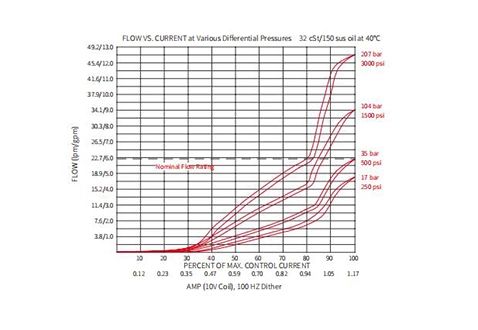

| Flow | 22 lpm (5.8 gpm) at 34.5 bar (500 psid) pressure drop. Minimum Operating Dither/Pulse Frequency: 70 Hz |

| Internal Leakage | 5 drops/min. at 250 bar (3600 psi) |

| E-Coi | Weight: 0.14 kg. (0.30 lbs.); Perfect wound, fully encapsulated with rugged external metal shell; Rated up to IP69K with integral connectors. |

| Standard Coil | Weight: 0.11 kg. (0.25 lbs.); Unitized thermoplastic encapsulated, Class H high temperature magnetwire. |

| Temperature | -40 to 120°C |

| Fluids |

Mineral - based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 ssu).Installation: No restrictions |

| Cartridge | Weight: 0.09 kg. (0.20 lbs.); Steel with hardened work surfaces. Zinc-plated exposed surfaces;Seal:O-rings and back-up rings. |

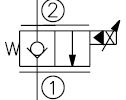

Product Operation Symbol

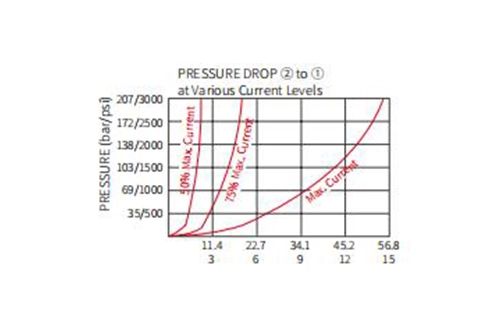

When de-energized, the 2-position 2-way proportional flow valve 20BL-08 acts as a check valve, allowing flow from ① to ②, and blocking flow from ② to ①. When energized, the ② to ① flow path is opened. Flow is proportional to the current applied to the coil. Flow varies with manual override.

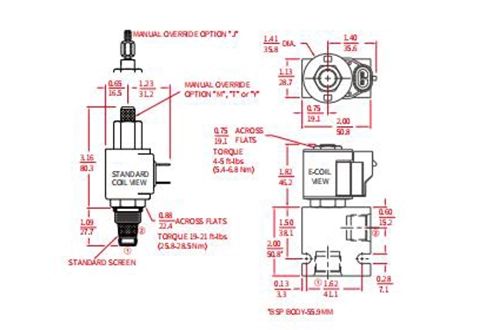

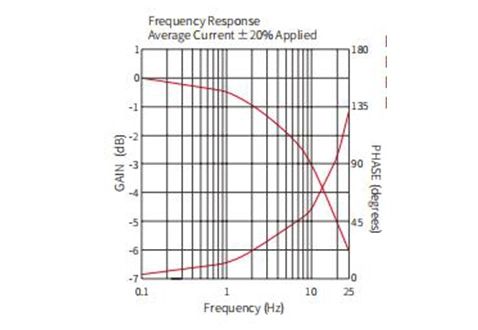

Performance/Dimension

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

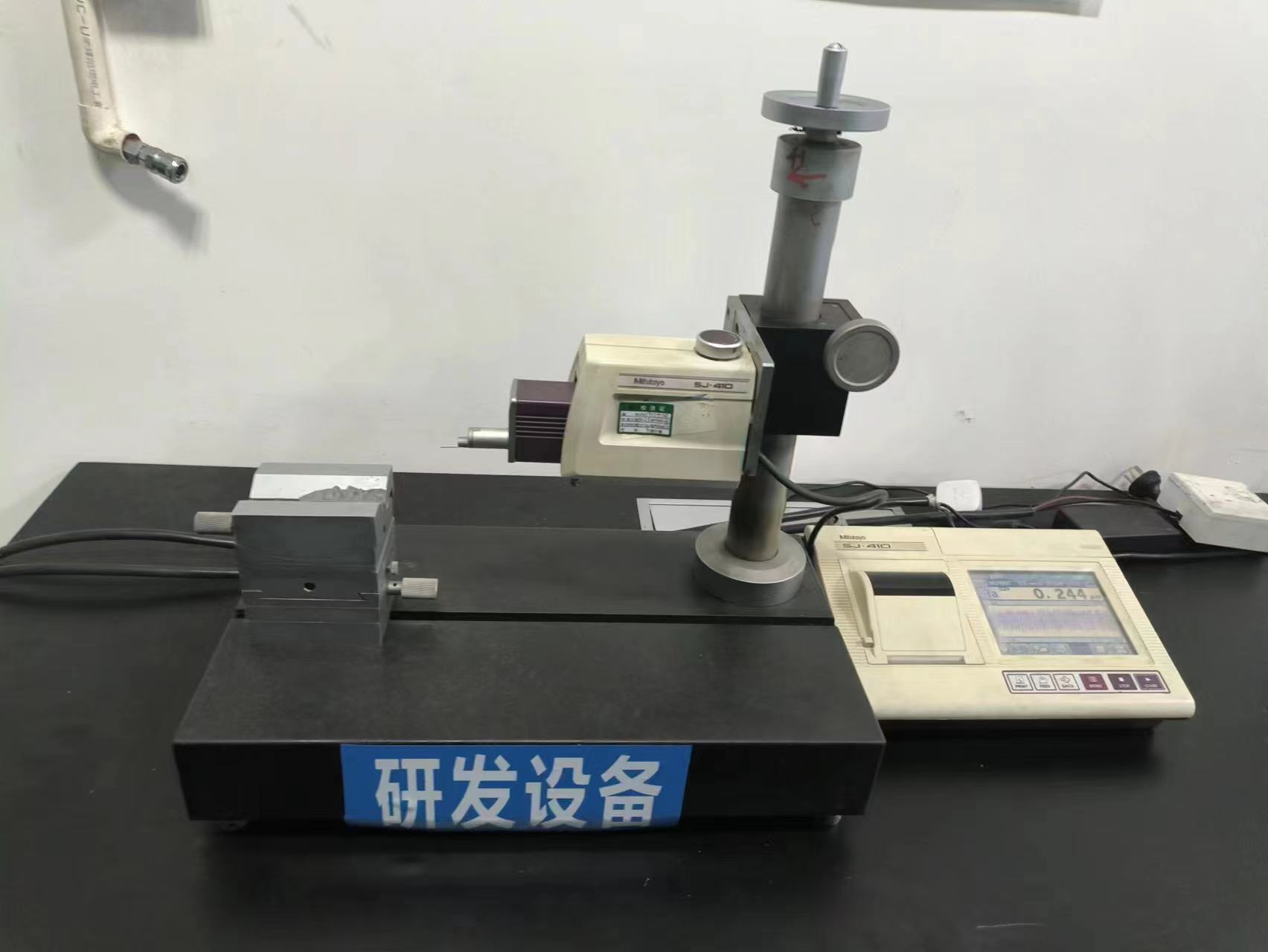

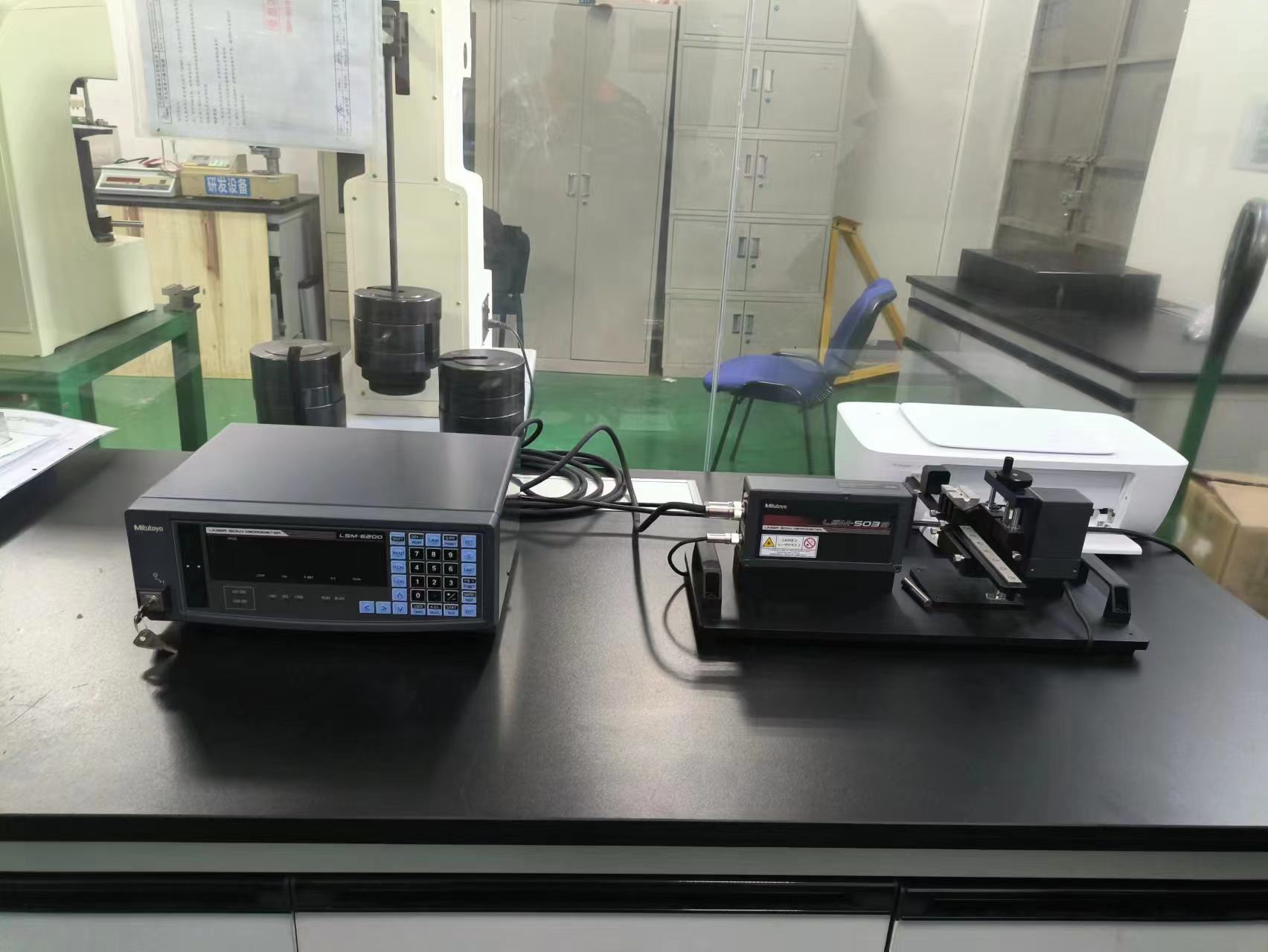

Quality Control

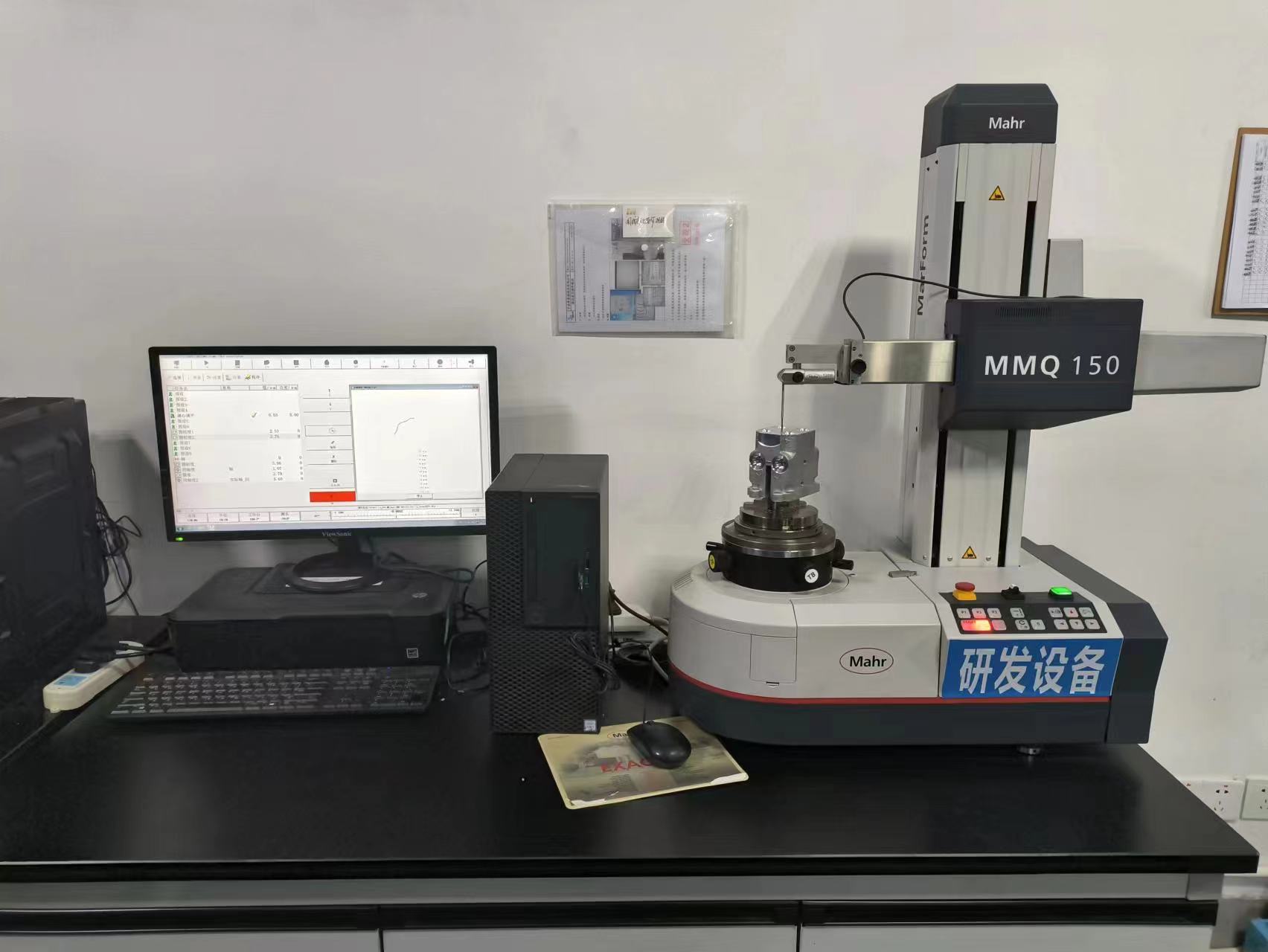

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.