20L-10 Hydraulic Needle Valve (throttle valve)

Product Features

1. Adjustments cannot be backed out of the valve.

2. Desired settings may be locked down.

3. Hardened parts for long life.

4. Industry common cavity.

5. Aluminum knob option.

6. Positive shut-off.

7. Linear adjustment.

Product Specifications

| Product Model | 20L-10 Hydraulic Needle Valve(throttle valve) |

| Operating Pressure | 250 bar (3600 psi) |

| Flow | 45 lpm (12 gpm) nominal at 7 bar (100 psi) differential at full open 3.5turns |

| Internal Leakage | 0.25 ml/min. (5 drop/minute) max. at shut-off |

| Adjustment Torque Required | 0.56 Nm (5 inch-pounds) at 7 bar (100 psi); 5.41 Nm (48 inch-pounds) at 207 bar (3000 psi) |

| Temperature | -40°℃~100°C |

| Fluids | Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 ssu). |

| Installation | No restrictions |

| Cartridge | Weight: 0.15 kg. (0.33 lbs.); Steel with hardened work surfaces. Zinc-plated exposed surfaces |

| Seal | D type seal rings; Anodized aluminum knobs. |

| Standard Ported Body | Weight: 0.16 kg. (0.35 lbs.); Anodized high-strength 6061 T6 aluminum alloy, rated to 240 bar (3500 psi). |

Product Operation Symbol

The 20L-10 increases its orifice value from fully closed to fully open with counterclockwise adjustment rotation.

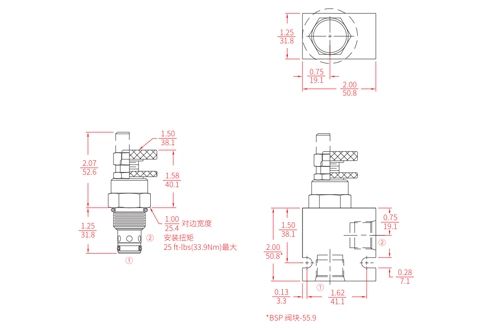

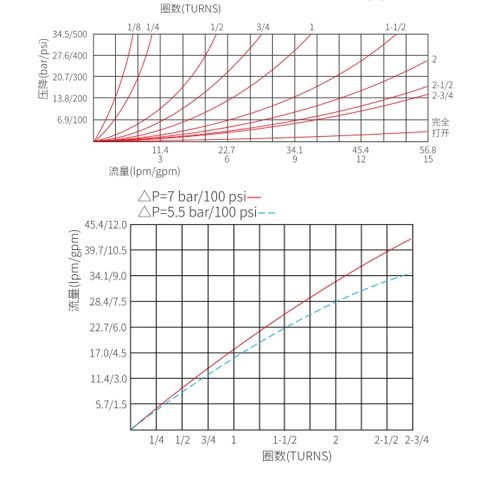

Performance/Dimension

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

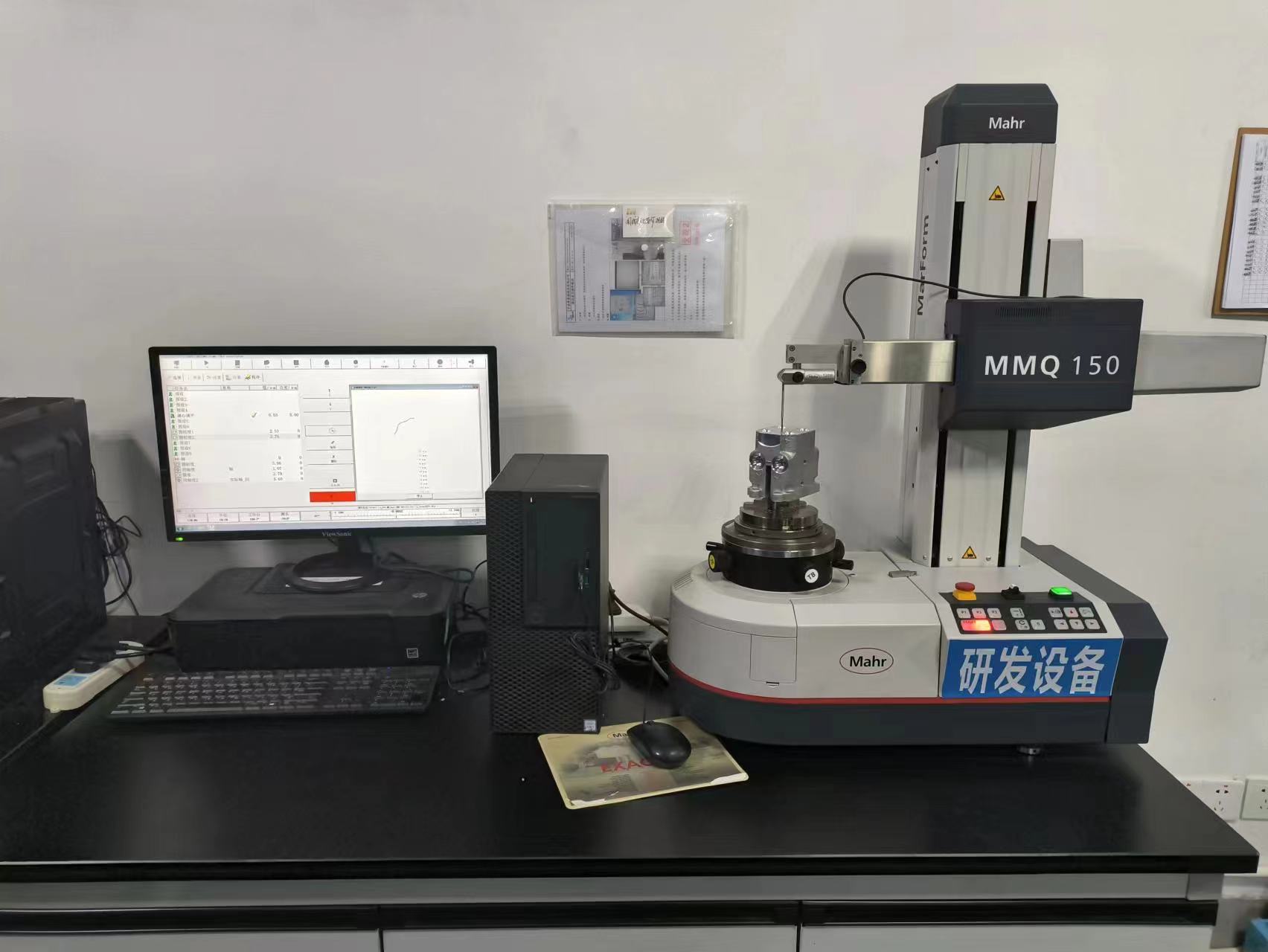

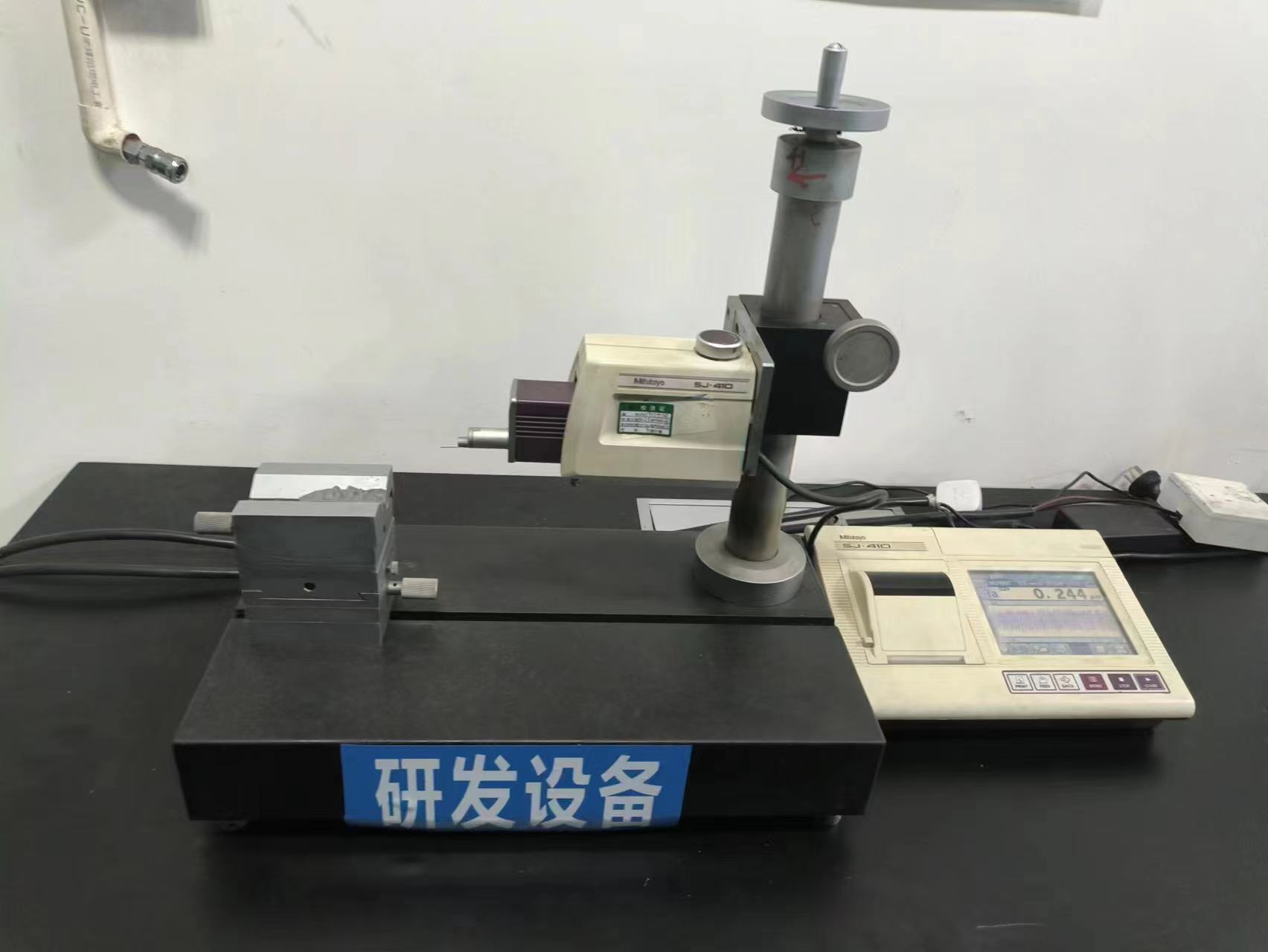

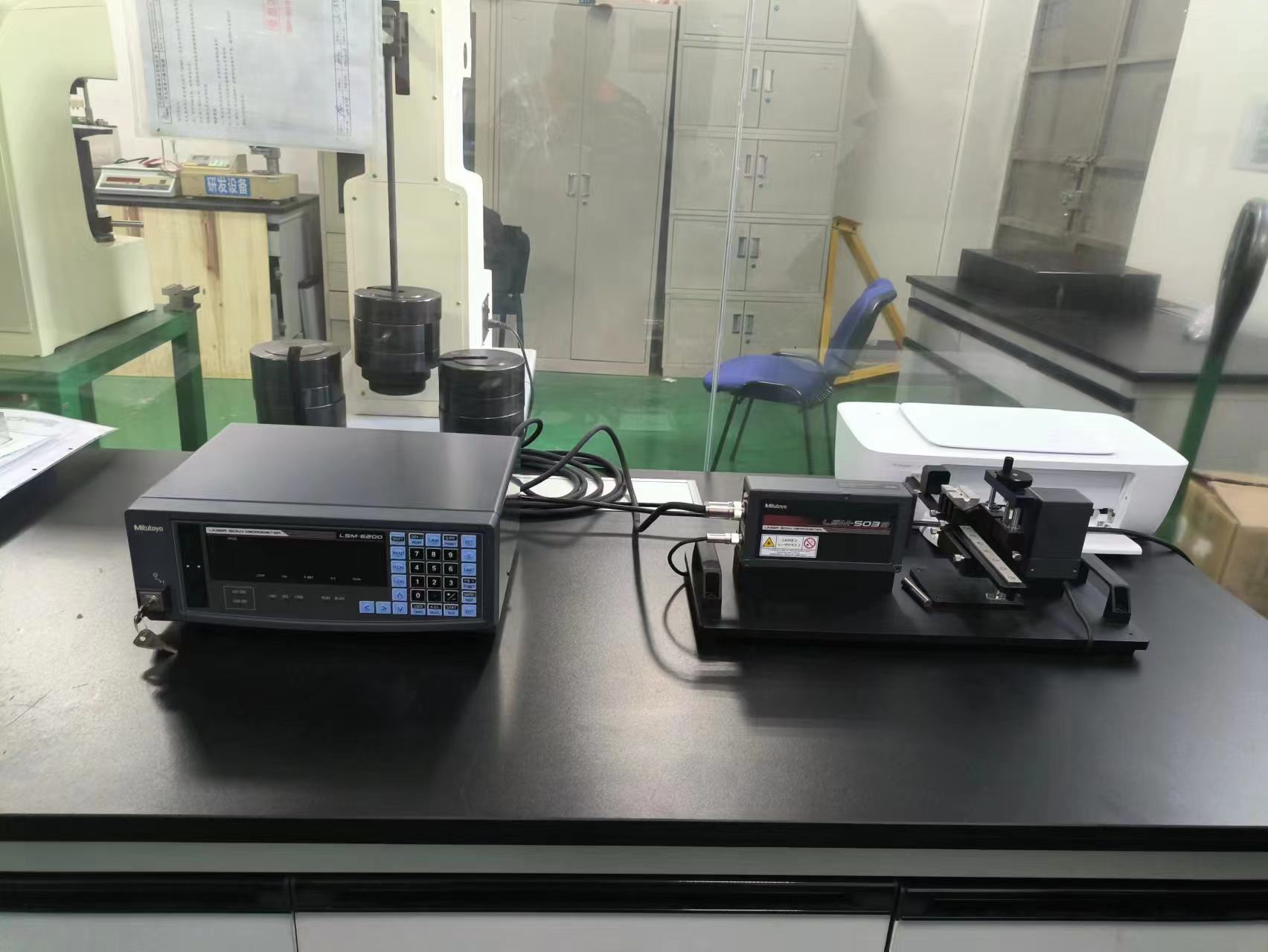

Quality Control

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.