Ball valve Check Valve 20A-10C

Product Features

1. Hardened seat for long life and low leakage.

2. Optional bias springs for back-pressure application flexibility.

3. Fully guided check assembly.

4. Miniature size.

5. Fast closing and seating.

Product Specifications

| Product Model | Ball valve Check Valve 20A-10C |

| Operating Pressure | 350 bar (5100 psi) |

| Proof Pressure | 525 bar (7500 psi) |

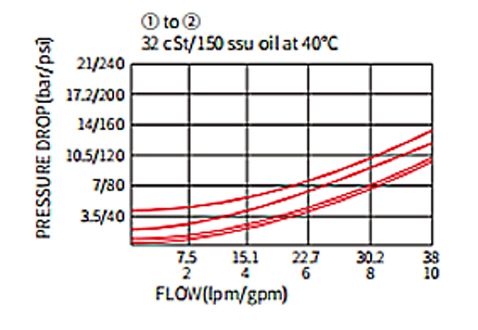

| Flow | See Performance Chart |

| Internal Leakage | 0.25 ml/min. (5 drops/minute) max. at 350 bar (5100 psi) |

| Crack Pressure Defined | Gauge bar (psi) evident at ① at 16.4 ml/min. (1 cu. in./minute) attained |

| Standard Bias Springs at Crack | 0.34 bar (5 psi);0.7 bar (10 psi);1.7 bar (25 psi);3.4 bar (50 psi);45 bar (650 psi) |

| Temperature | -40°℃~120°C |

| Fluids | Mineral-based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 ssu). |

| Installation | No restrictions |

| Cartridge | Weight: 0.12 kg. (0.26 lbs.); Steel with hardened work surfaces. Zinc-Nickel-plated exposed surfaces.Seal: Buna-N O-rings and back-up rings (standard). |

| Standard Ported Body | Weight: 0.14 kg. (0.31 lbs.); Anodized highstrength 6061 T6 aluminum alloy, rated to 240 bar (3500 psi). |

Ductile iron and steel bodies available; dimensions may differ Consult Flag.

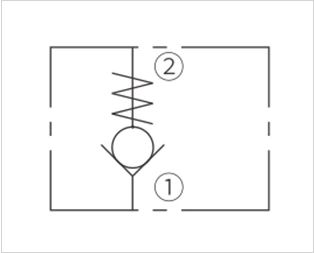

Product Operation Symbol

The Ball valve Check Valve 20A-10C allow flow passage from ① to ②, while normally blocking oil flow in the opposite direction. The cartridge has a fully guided check which is spring-biased closed until sufficient pressure is applied at ① to open ②.

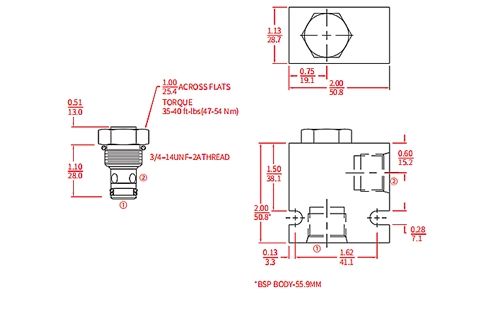

Performance/Dimension