Counterbalance Valve 30PH-S120-4.5

Product Features

The Counterbalance Valve 30PH-S120-4.5 is a sophisticated and versatile hydraulic valve designed to provide precise control and stability in a variety of industrial applications. This valve plays a critical role in maintaining balance and preventing uncontrolled movements of hydraulic cylinders, ensuring optimal performance and safety.

One of the key features of the Counterbalance Valve 30PH-S120-4.5 is its ability to control the flow of hydraulic fluid in a counteractive manner. This means that it regulates the flow by offsetting the pressure exerted by the load on the cylinder, effectively counterbalancing it. By doing so, it prevents uncontrolled movements, such as free-fall or involuntary lowering, enhancing the overall operational efficiency and preventing potential accidents or damage.

Constructed with high-grade materials, the Counterbalance Valve 30PH-S120-4.5 is highly durable and resistant to adverse conditions. Its robust design enables it to withstand heavy loads, extreme pressures, and high temperatures, making it suitable for harsh operating environments found in industries such as construction, agriculture, and material handling.

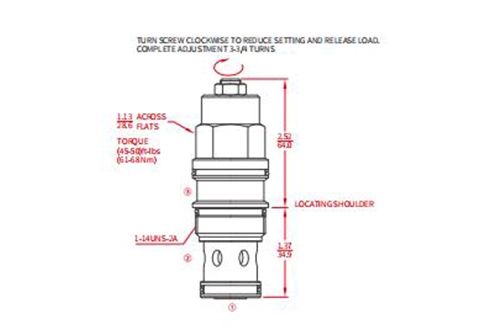

The valve is designed for easy installation and integration into existing hydraulic systems. Its standard port size of 10A ensures compatibility with a wide range of system connections, providing flexibility and ease of use. The valve's compact size allows for space-saving installations and ensures efficient use of available resources.

In terms of performance, the Counterbalance Valve 30PH-S120-4.5 offers precise control and response times. It is equipped with adjustable pressure settings, allowing operators to fine-tune the valve's behavior according to specific application requirements. This feature ensures accurate and consistent operation, even in situations where the load or working conditions vary.

Product Specifications

| Product Model | Counterbalance Valve 30PH-S120-4.5 |

| Operating Pressure | Loading pressure max. 215 bar when setting pressure at 280bar |

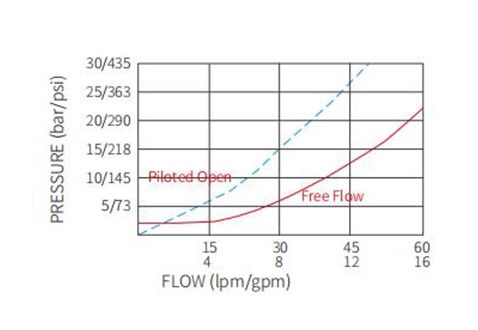

| Flow | See Performance Chart |

| Internal Leakage | Max. 0.4 ml/min. at Reseat; Reseat pressure > 85% of setting pressure; Factory pressure settings established at flow of 32.8 ml/min |

| Pilot Ratio | 3:1, max. setting should be equal to 1.3 times the load pressure |

| Temperature | -40 to 120°C |

| Fluids |

Mineral - based or synthetics with lubricating properties at viscosities of 7.4 to 420 cSt (50 to 2000 ssu).Installation: No restrictions |

| Cartridge | Weight: 0.20 kg. (0.44 lbs.); Steel with hardened work surfaces. Zinc-plated exposed surfaces. Seal: O-rings and back-up rings. |

Product Operation Symbol

Safety is of utmost importance, and the Counterbalance Valve 30PH-S120-4.5 incorporates various safety features. Its built-in pressure relief mechanism safeguards against excessive pressure buildup, preventing potential system failures or damage. Additionally, the valve's pilot-operated design ensures reliable and stable operation, maintaining consistent flow control and preventing sudden movements.

In conclusion, the Counterbalance Valve 30PH-S120-4.5 offers exceptional control, stability, and safety in hydraulic systems. Its robust construction, precise performance, and adjustable settings make it an ideal choice for demanding applications that require precise load control. With its innovative design and reliable operation, this valve contributes to the overall efficiency and safety of hydraulic systems across various industries.

Performance/Dimension

WHY CHOOSE US

How we work

Development (tell us your machine model or design)

Quotation (we will provide you with a quotation as soon as possible)

Samples (samples will be sent to you for quality inspection)

Order (placed after confirming quantity and delivery time, etc.)

Design (for your product)

Production (producing goods according to customer requirements)

QC (Our QC team will inspect the products and provide QC reports)

Loading (loading ready-made inventory into customer containers)

Our Certificate

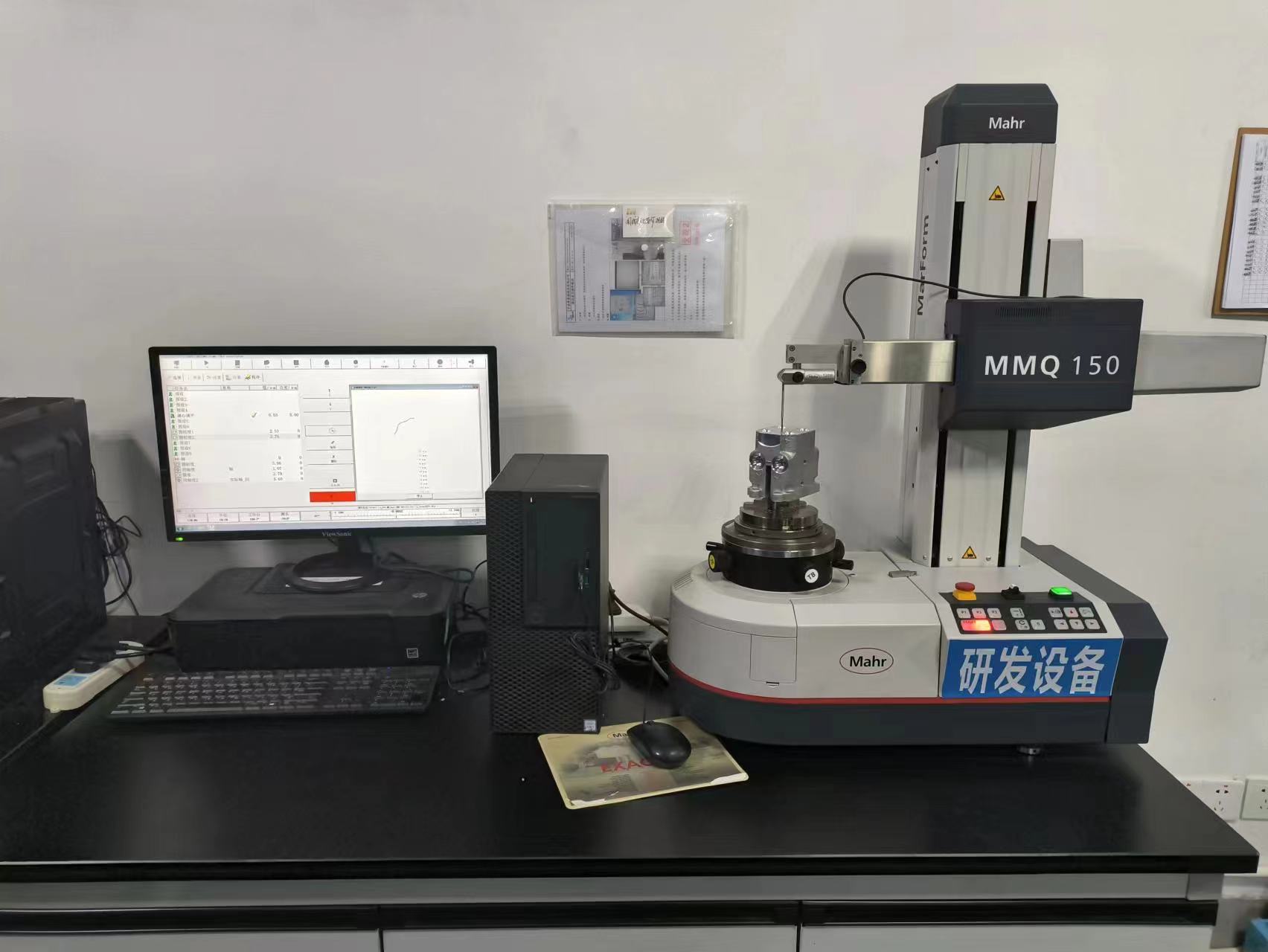

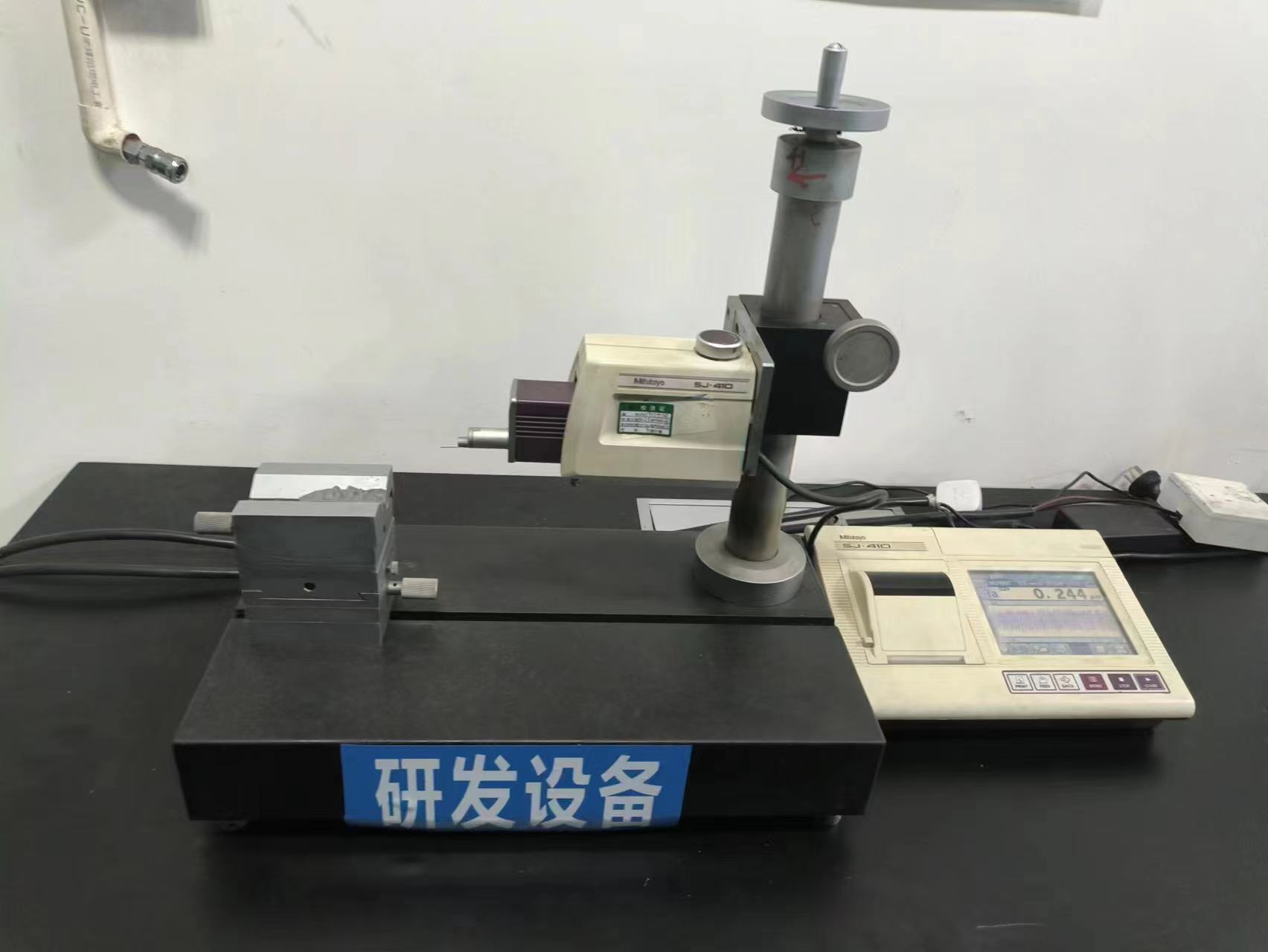

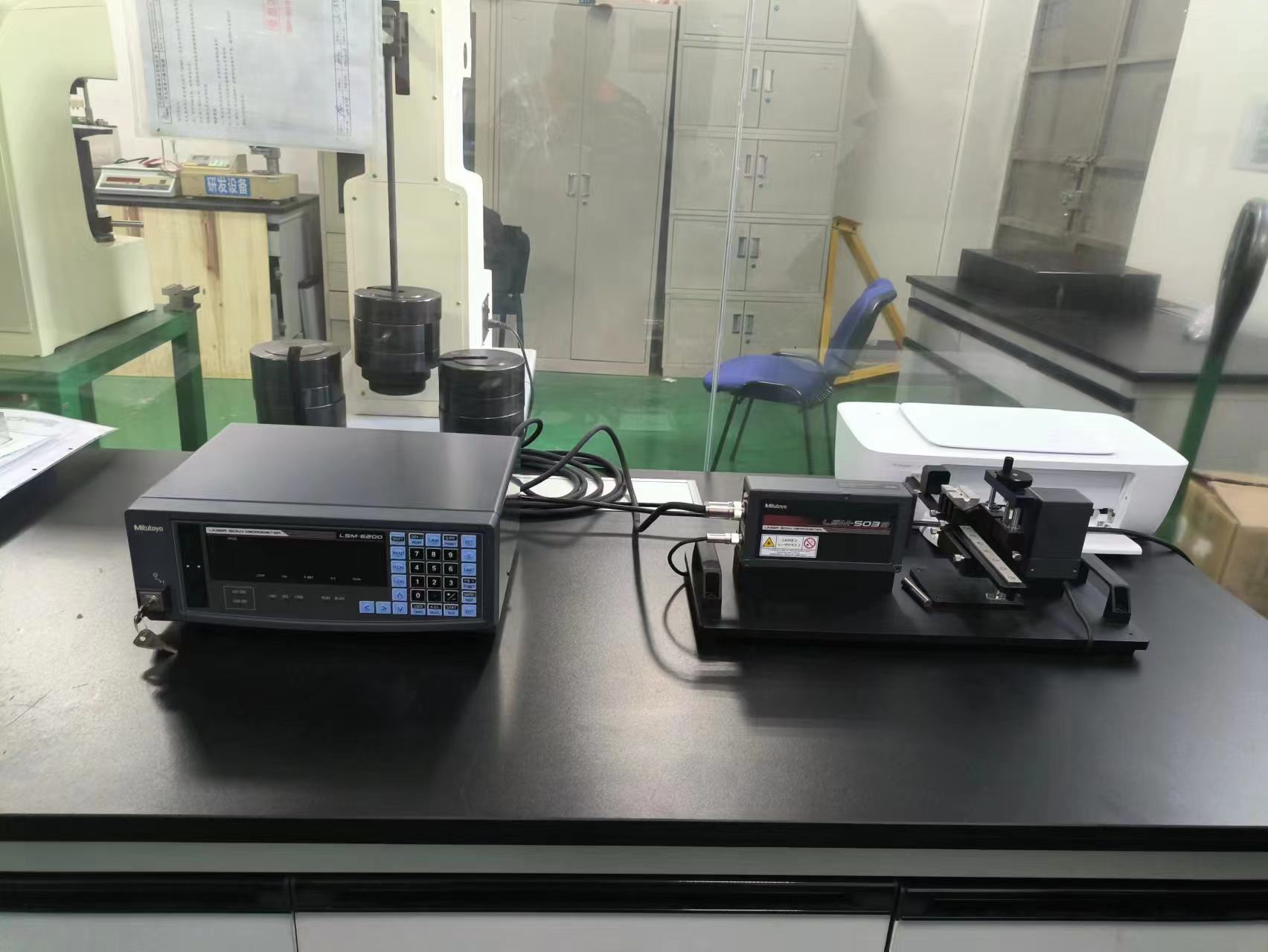

Quality Control

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.